Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

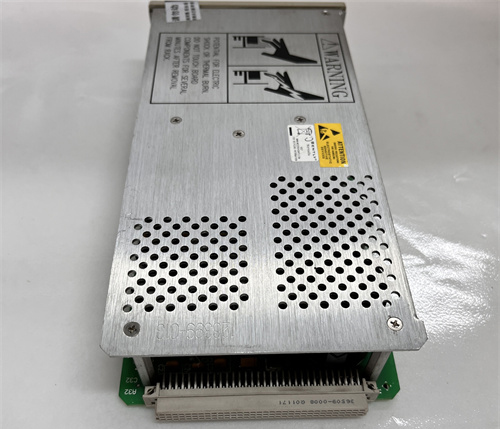

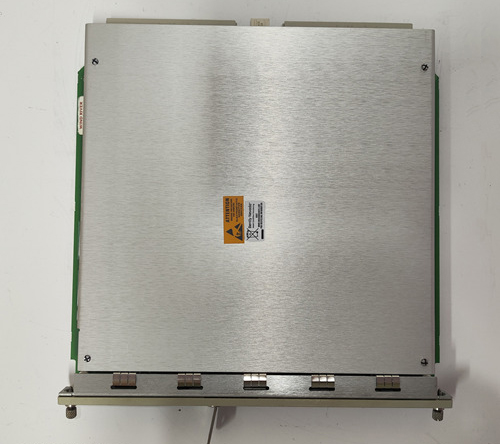

Bently Nevada 164517-050-10-01-RU 3300 XL Ceramic Capped Proximity Probes

Manufacturer:Bently Nevada

Product Number:164517-050-10-01-RU

Product Type:3300 XL Ceramic Capped Proximity Probes

Origin:USA

Total Length:1 meter

Shipping Weight:3 kg

Views:119

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 164517-050-10-01-RU 3300 XL Ceramic Capped Proximity Probe is a high-precision industrial sensor designed for continuous monitoring of rotating machinery. Its ceramic-capped tip provides enhanced wear resistance and stable measurement performance under harsh industrial conditions, making it particularly suitable for turbines, compressors, pumps, and motors.

The 3300 XL series probes are engineered to maintain accurate eddy-current measurements of shaft position and vibration, ensuring early detection of imbalance, misalignment, or mechanical degradation. This model is compatible with Bently Nevada 3300 XL monitoring systems and other 3300 XL series signal conditioners, providing seamless integration into existing machinery protection networks.

Constructed with durable materials and a rugged design, the 3300 XL Ceramic Capped Probe delivers reliable operation in high-temperature, high-vibration, and chemically aggressive environments, reducing the risk of sensor failure and maintenance interventions.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 164517-050-10-01-RU |

| Type | 3300 XL Ceramic Capped Proximity Probe |

| Compatible Systems | Bently Nevada 3300 XL Series Monitors |

| Probe Tip Material | Ceramic |

| Housing Material | Stainless steel |

| Operating Temperature Range | -40°C to +125°C |

| Environmental Protection | Oil, coolant, and chemical resistant |

| Output Signal | Eddy current analog signal |

| Tip Cap Type | Ceramic, wear-resistant |

| Total Length | 1 meter |

| Shipping Weight | 3 kg |

| Mounting | Standard threaded or custom mounting available |

Applications

The 3300 XL Ceramic Capped Proximity Probe is used in a wide variety of critical machinery monitoring applications:

Turbine Monitoring: Provides precise shaft vibration and position data for steam, gas, and hydro turbines.

Compressor Protection: Detects early signs of mechanical stress or imbalance.

Pump Health Monitoring: Measures shaft motion and vibration to prevent failures.

Motor Condition Monitoring: Supports predictive maintenance through real-time vibration analysis.

Industrial Process Safety: Integrates with monitoring networks for alarms and automatic shutdowns during abnormal conditions.

Retrofit and Upgrade Projects: Replaces older proximity probes with minimal modification to existing monitoring systems.

Advantages

Ceramic Tip Durability: Resists wear and maintains stable readings over long periods, even in high-speed machinery.

High Precision: Accurate eddy-current measurements for shaft vibration and position.

Industrial Reliability: Withstands oil, chemicals, vibration, and extreme temperatures.

Seamless Integration: Fully compatible with 3300 XL Series Monitors and other 300 XL signal conditioners.

Flexible Mounting Options: Supports standard threaded or custom installations.

Reduced Maintenance: Long-lasting ceramic tip and rugged construction minimize service intervals.

Enhanced Machine Protection: Enables early detection of mechanical issues, reducing risk of unplanned downtime.

FAQ

What types of monitoring systems are compatible with this probe?

It is compatible with Bently Nevada 3300 XL Series Monitors and other 300 XL series signal conditioners.

What is the material of the probe tip?

The tip is made of ceramic, providing wear resistance and stable measurements.

Can this probe operate in high-temperature environments?

Yes, it functions reliably within a range of -40°C to +125°C.

Is the probe resistant to industrial chemicals and oils?

Yes, the stainless steel housing and tip materials are designed to withstand oils, coolants, and common industrial chemicals.

What type of output signal does the probe provide?

The probe generates an eddy-current analog signal proportional to shaft displacement.

How is the probe mounted on machinery?

It supports standard threaded mounting and can also accommodate custom mounting arrangements.

Can it be used in high-vibration machinery?

Yes, it is engineered to maintain stable and accurate readings under high mechanical vibration.

Does the ceramic tip improve long-term measurement stability?

Yes, the ceramic tip reduces wear and ensures consistent eddy-current signal output over time.

Is the probe compatible with retrofit installations?

Yes, it can replace older 300 XL series probes with minimal adjustments.

Does the probe require special calibration?

It is factory-calibrated for standard 3300 XL Monitors; site calibration may be performed for specific machinery configurations.

Bently Nevada 164517-050-10-01-RU 3300 XL Ceramic Capped Proximity Probes

Manufacturer:Bently Nevada

Product Number:164517-050-10-01-RU

Product Type:3300 XL Ceramic Capped Proximity Probes

Origin:USA

Total Length:1 meter

Shipping Weight:3 kg

Views:119

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 164517-050-10-01-RU 3300 XL Ceramic Capped Proximity Probe is a high-precision industrial sensor designed for continuous monitoring of rotating machinery. Its ceramic-capped tip provides enhanced wear resistance and stable measurement performance under harsh industrial conditions, making it particularly suitable for turbines, compressors, pumps, and motors.

The 3300 XL series probes are engineered to maintain accurate eddy-current measurements of shaft position and vibration, ensuring early detection of imbalance, misalignment, or mechanical degradation. This model is compatible with Bently Nevada 3300 XL monitoring systems and other 3300 XL series signal conditioners, providing seamless integration into existing machinery protection networks.

Constructed with durable materials and a rugged design, the 3300 XL Ceramic Capped Probe delivers reliable operation in high-temperature, high-vibration, and chemically aggressive environments, reducing the risk of sensor failure and maintenance interventions.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 164517-050-10-01-RU |

| Type | 3300 XL Ceramic Capped Proximity Probe |

| Compatible Systems | Bently Nevada 3300 XL Series Monitors |

| Probe Tip Material | Ceramic |

| Housing Material | Stainless steel |

| Operating Temperature Range | -40°C to +125°C |

| Environmental Protection | Oil, coolant, and chemical resistant |

| Output Signal | Eddy current analog signal |

| Tip Cap Type | Ceramic, wear-resistant |

| Total Length | 1 meter |

| Shipping Weight | 3 kg |

| Mounting | Standard threaded or custom mounting available |

Applications

The 3300 XL Ceramic Capped Proximity Probe is used in a wide variety of critical machinery monitoring applications:

Turbine Monitoring: Provides precise shaft vibration and position data for steam, gas, and hydro turbines.

Compressor Protection: Detects early signs of mechanical stress or imbalance.

Pump Health Monitoring: Measures shaft motion and vibration to prevent failures.

Motor Condition Monitoring: Supports predictive maintenance through real-time vibration analysis.

Industrial Process Safety: Integrates with monitoring networks for alarms and automatic shutdowns during abnormal conditions.

Retrofit and Upgrade Projects: Replaces older proximity probes with minimal modification to existing monitoring systems.

Advantages

Ceramic Tip Durability: Resists wear and maintains stable readings over long periods, even in high-speed machinery.

High Precision: Accurate eddy-current measurements for shaft vibration and position.

Industrial Reliability: Withstands oil, chemicals, vibration, and extreme temperatures.

Seamless Integration: Fully compatible with 3300 XL Series Monitors and other 300 XL signal conditioners.

Flexible Mounting Options: Supports standard threaded or custom installations.

Reduced Maintenance: Long-lasting ceramic tip and rugged construction minimize service intervals.

Enhanced Machine Protection: Enables early detection of mechanical issues, reducing risk of unplanned downtime.

FAQ

What types of monitoring systems are compatible with this probe?

It is compatible with Bently Nevada 3300 XL Series Monitors and other 300 XL series signal conditioners.

What is the material of the probe tip?

The tip is made of ceramic, providing wear resistance and stable measurements.

Can this probe operate in high-temperature environments?

Yes, it functions reliably within a range of -40°C to +125°C.

Is the probe resistant to industrial chemicals and oils?

Yes, the stainless steel housing and tip materials are designed to withstand oils, coolants, and common industrial chemicals.

What type of output signal does the probe provide?

The probe generates an eddy-current analog signal proportional to shaft displacement.

How is the probe mounted on machinery?

It supports standard threaded mounting and can also accommodate custom mounting arrangements.

Can it be used in high-vibration machinery?

Yes, it is engineered to maintain stable and accurate readings under high mechanical vibration.

Does the ceramic tip improve long-term measurement stability?

Yes, the ceramic tip reduces wear and ensures consistent eddy-current signal output over time.

Is the probe compatible with retrofit installations?

Yes, it can replace older 300 XL series probes with minimal adjustments.

Does the probe require special calibration?

It is factory-calibrated for standard 3300 XL Monitors; site calibration may be performed for specific machinery configurations.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...