Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

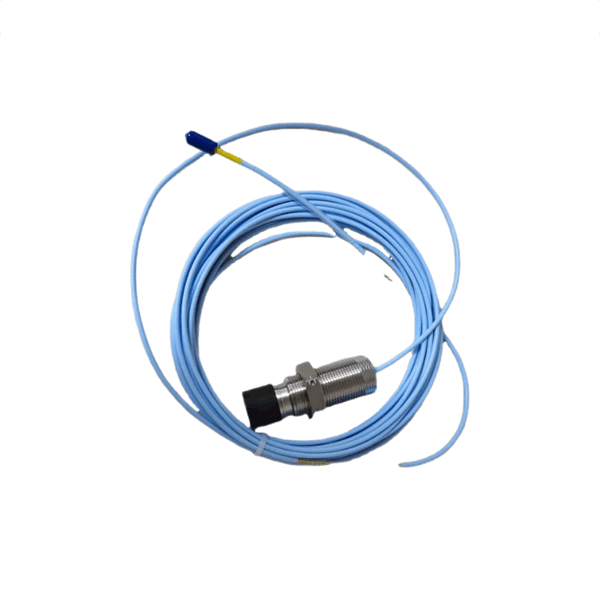

Bently Nevada 330851-02-000-050-90-00-00 3300 XL 25 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330851-02-000-050-90-00-00

Product Type:3300 XL 25 mm Proximity Probe

Origin:USA

Total Length:9 m

Weight :0.59 kg

Views:17

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330851-02-000-050-90-00-00 is a 3300 XL 25 mm Proximity Probe, designed for high-precision vibration measurement in rotating machinery. This probe is part of the 3300 XL system, renowned for providing reliable and accurate data for machinery protection and condition monitoring. With its robust design and stable signal output, it ensures consistent monitoring even in demanding industrial environments.

The 25 mm probe is optimized for clearance measurements and proximity monitoring in turbines, compressors, pumps, and other high-speed machinery. It integrates seamlessly with Bently Nevada’s 3300 XL monitoring system, allowing real-time protection and diagnostics to prevent catastrophic failures.

Technical Specifications

| Parameter | Specification |

|---|---|

| Probe Type | AC Voltage / Eddy Current |

| Sensing Range | 25 mm |

| Output Signal | Differential AC voltage |

| Operating Temperature Range | -40°C to +120°C |

| Total Length | 9 m |

| Weight | 0.59 kg |

| Tip Material | Non-magnetic stainless steel |

| Cable Type | Shielded coaxial cable |

| Connector Type | Standard Bently connector |

| System Compatibility | 3300 XL System |

| Maximum Shaft Speed | As per 3300 XL system specifications |

| Environmental Protection | IP65 (probe tip), suitable for industrial environments |

Product Applications

-

Machinery vibration monitoring and protection in rotating equipment.

-

Clearance and shaft displacement measurements in turbines, generators, compressors, and pumps.

-

Continuous condition monitoring for early detection of misalignment, imbalance, or shaft rubs.

-

Integration into plant-wide predictive maintenance systems.

-

Industrial applications in power generation, oil & gas, petrochemical, and heavy manufacturing sectors.

Product Advantages

High Accuracy: Provides precise measurements for early detection of mechanical issues.

Reliable in Harsh Environments: Designed to operate under high temperatures, vibration, and moisture conditions.

Seamless System Integration: Fully compatible with the Bently Nevada 3300 XL monitoring system.

Long Cable Option: 9 m total length ensures flexible installation and reduces need for extensions.

Robust Construction: Non-magnetic stainless steel tip resists wear and maintains consistent readings.

Industry Standard: Trusted in critical applications worldwide for over decades.

FAQ

Q1: Can this probe measure shaft vibration in high-speed turbines?

Yes, the 25 mm proximity probe is suitable for high-speed turbines and provides accurate vibration and clearance measurements.

Q2: Is this probe compatible with all Bently Nevada 3300 XL modules?

It is compatible with all standard 3300 XL monitoring modules, but always verify system configuration and cable compatibility.

Q3: What type of output signal does this probe provide?

It provides a differential AC voltage output compatible with 3300 XL proximity monitoring inputs.

Q4: Can the probe operate in extreme temperatures?

Yes, the operating range is -40°C to +120°C, suitable for most industrial environments.

Q5: How is the probe mounted on machinery?

It is installed using standard mounting hardware provided by Bently Nevada, typically in proximity to the monitored shaft.

Q6: Does the probe cable require shielding?

Yes, it comes with a shielded coaxial cable to minimize electrical noise and ensure accurate readings.

Q7: Can this probe be used in explosive or hazardous areas?

The probe itself is designed for industrial conditions. Use in hazardous areas must comply with additional certifications and installation standards.

Q8: How does the 25 mm sensing range affect measurement accuracy?

The 25 mm range provides precise clearance detection while maintaining sensitivity for displacement and vibration analysis.

Q9: Is there any special maintenance required?

Routine inspection of cable integrity and tip cleanliness is recommended to maintain optimal performance.

Q10: Can this probe detect misalignment or shaft rubs?

Yes, the probe provides high-resolution displacement signals capable of detecting misalignment, imbalance, and rub conditions in rotating machinery.

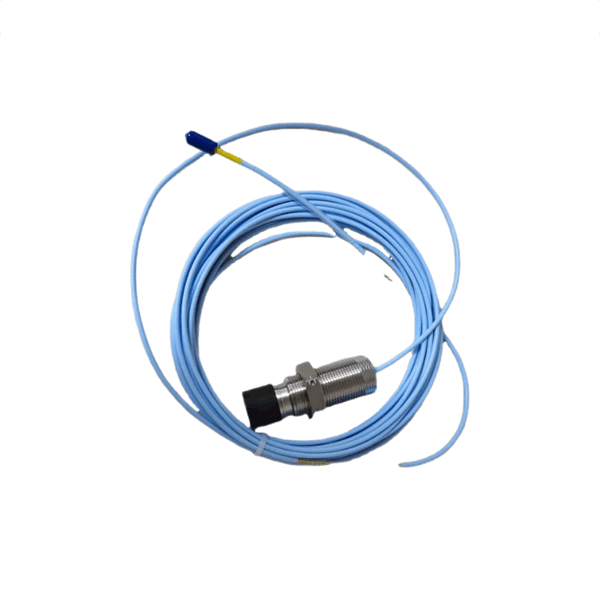

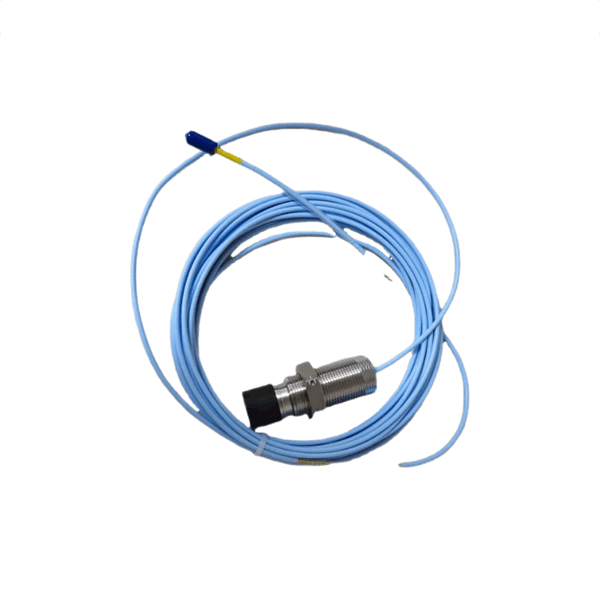

Bently Nevada 330851-02-000-050-90-00-00 3300 XL 25 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330851-02-000-050-90-00-00

Product Type:3300 XL 25 mm Proximity Probe

Origin:USA

Total Length:9 m

Weight :0.59 kg

Views:17

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330851-02-000-050-90-00-00 is a 3300 XL 25 mm Proximity Probe, designed for high-precision vibration measurement in rotating machinery. This probe is part of the 3300 XL system, renowned for providing reliable and accurate data for machinery protection and condition monitoring. With its robust design and stable signal output, it ensures consistent monitoring even in demanding industrial environments.

The 25 mm probe is optimized for clearance measurements and proximity monitoring in turbines, compressors, pumps, and other high-speed machinery. It integrates seamlessly with Bently Nevada’s 3300 XL monitoring system, allowing real-time protection and diagnostics to prevent catastrophic failures.

Technical Specifications

| Parameter | Specification |

|---|---|

| Probe Type | AC Voltage / Eddy Current |

| Sensing Range | 25 mm |

| Output Signal | Differential AC voltage |

| Operating Temperature Range | -40°C to +120°C |

| Total Length | 9 m |

| Weight | 0.59 kg |

| Tip Material | Non-magnetic stainless steel |

| Cable Type | Shielded coaxial cable |

| Connector Type | Standard Bently connector |

| System Compatibility | 3300 XL System |

| Maximum Shaft Speed | As per 3300 XL system specifications |

| Environmental Protection | IP65 (probe tip), suitable for industrial environments |

Product Applications

-

Machinery vibration monitoring and protection in rotating equipment.

-

Clearance and shaft displacement measurements in turbines, generators, compressors, and pumps.

-

Continuous condition monitoring for early detection of misalignment, imbalance, or shaft rubs.

-

Integration into plant-wide predictive maintenance systems.

-

Industrial applications in power generation, oil & gas, petrochemical, and heavy manufacturing sectors.

Product Advantages

High Accuracy: Provides precise measurements for early detection of mechanical issues.

Reliable in Harsh Environments: Designed to operate under high temperatures, vibration, and moisture conditions.

Seamless System Integration: Fully compatible with the Bently Nevada 3300 XL monitoring system.

Long Cable Option: 9 m total length ensures flexible installation and reduces need for extensions.

Robust Construction: Non-magnetic stainless steel tip resists wear and maintains consistent readings.

Industry Standard: Trusted in critical applications worldwide for over decades.

FAQ

Q1: Can this probe measure shaft vibration in high-speed turbines?

Yes, the 25 mm proximity probe is suitable for high-speed turbines and provides accurate vibration and clearance measurements.

Q2: Is this probe compatible with all Bently Nevada 3300 XL modules?

It is compatible with all standard 3300 XL monitoring modules, but always verify system configuration and cable compatibility.

Q3: What type of output signal does this probe provide?

It provides a differential AC voltage output compatible with 3300 XL proximity monitoring inputs.

Q4: Can the probe operate in extreme temperatures?

Yes, the operating range is -40°C to +120°C, suitable for most industrial environments.

Q5: How is the probe mounted on machinery?

It is installed using standard mounting hardware provided by Bently Nevada, typically in proximity to the monitored shaft.

Q6: Does the probe cable require shielding?

Yes, it comes with a shielded coaxial cable to minimize electrical noise and ensure accurate readings.

Q7: Can this probe be used in explosive or hazardous areas?

The probe itself is designed for industrial conditions. Use in hazardous areas must comply with additional certifications and installation standards.

Q8: How does the 25 mm sensing range affect measurement accuracy?

The 25 mm range provides precise clearance detection while maintaining sensitivity for displacement and vibration analysis.

Q9: Is there any special maintenance required?

Routine inspection of cable integrity and tip cleanliness is recommended to maintain optimal performance.

Q10: Can this probe detect misalignment or shaft rubs?

Yes, the probe provides high-resolution displacement signals capable of detecting misalignment, imbalance, and rub conditions in rotating machinery.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...