Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

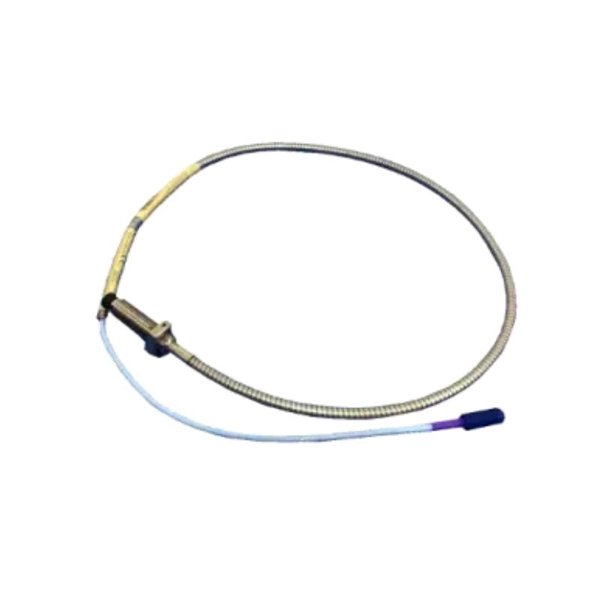

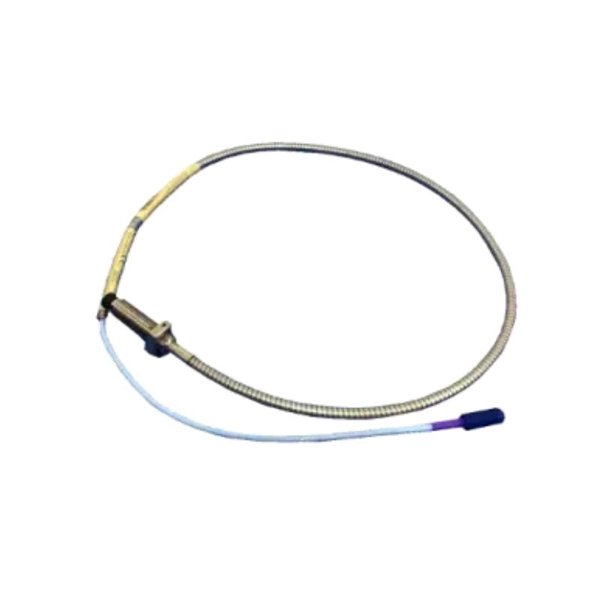

Bently Nevada 330173-08-18-10-02-00 3300 5mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330173-08-18-10-02-00

Product Type:3300 5mm Proximity Probe

Origin:USA

Total Length:1 meter

Weight:0.323 kg

Views:124

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330173-08-18-10-02-00 3300 5mm Proximity Probe is part of the industry-proven 3300 series proximity transducers, designed for highly reliable machinery condition monitoring and protection systems. This model features a 5 mm probe tip, a 1.0 meter total length, and rugged coaxial construction, ensuring consistent performance in challenging industrial environments.

The probe operates on eddy-current technology, delivering precise non-contact measurements of shaft vibration and displacement. With its compliance to API 670 standards, it has become a trusted choice in critical applications such as turbines, compressors, and other high-speed rotating machinery. Its stainless-steel housing, electrical isolation, and IP65 protection make it durable for long-term operation in environments with high temperatures, dust, and oil exposure.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330173-08-18-10-02-00 |

| Series | Bently Nevada 3300 Series |

| Probe Type | 5 mm Proximity Probe |

| Tip Diameter | 5 mm |

| Total Length | 1.0 meter |

| Cable Type | Rugged coaxial with shielding |

| Connector Type | Standard coaxial connector |

| Housing Material | Stainless Steel |

| Frequency Response | 0 Hz to 10 kHz |

| Linearity Error | ±1% of full-scale output |

| Operating Temperature | -35°C to +120°C |

| Storage Temperature | -50°C to +150°C |

| Electrical Isolation | Ground-isolated |

| Environmental Rating | IP65 |

| Compliance | API 670, CE, RoHS |

| Weight | 0.323 kg |

Product Applications

The 330173-08-18-10-02-00 is widely used in machinery protection and predictive maintenance systems, including:

Gas and Steam Turbines – Detecting shaft vibration, axial position, and thermal growth.

Compressors – Monitoring imbalance, misalignment, and rotor stability.

Electric Motors and Generators – Ensuring safe operating limits are maintained.

Industrial Pumps – Early detection of bearing degradation and cavitation issues.

Petrochemical and Refining Equipment – Providing continuous monitoring for safety-critical operations.

Heavy-Duty Machinery – Supporting long-term reliability in power plants and manufacturing facilities.

Product Advantages

High Accuracy – ±1% linearity error ensures dependable measurements.

Durable Build – Stainless steel housing and rugged coaxial cable withstand harsh conditions.

Noise Resistance – Shielded design minimizes electromagnetic interference.

Versatile Frequency Range – Suitable for static shaft position and dynamic vibration monitoring.

Full API 670 Compliance – Approved for machine protection systems.

Ground Isolation – Prevents electrical noise coupling into monitoring circuits.

Extended Temperature Tolerance – Operates reliably across a wide thermal range.

Predictive Maintenance Support – Provides critical data for failure prevention strategies.

FAQ

What sensing technology does this probe use?

It uses eddy-current technology to detect shaft displacement and vibration.

Can this probe monitor both static and dynamic signals?

Yes, it can measure static shaft position and dynamic vibration simultaneously.

What is the frequency response capability of this model?

It supports accurate measurements from 0 Hz to 10 kHz.

How does the coaxial shielding improve performance?

It minimizes electromagnetic interference, ensuring clean signal transmission.

Is the probe electrically isolated from the machine shaft?

Yes, it is designed with ground isolation to prevent signal noise.

Does this probe comply with API 670 standards?

Yes, it is fully compliant with API 670 for machinery protection systems.

Can it be used interchangeably with other 330173 series probes?

Yes, but proper matching with proximitor modules and calibration is required.

What types of machinery faults can it help detect?

It can identify imbalance, misalignment, bearing wear, and rotor instability.

How does it maintain accuracy under high temperatures?

It is built with robust materials and insulation rated for extended thermal ranges.

Is this probe compatible with existing Bently Nevada monitoring systems?

Yes, it integrates seamlessly with proximitor sensors and monitoring modules.

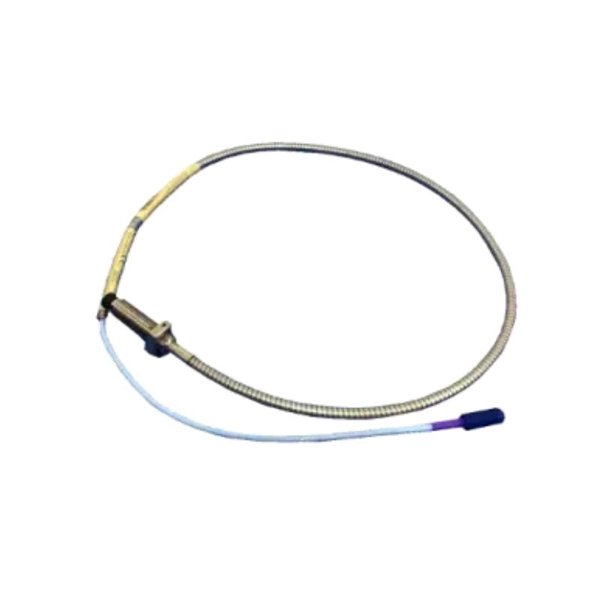

Bently Nevada 330173-08-18-10-02-00 3300 5mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330173-08-18-10-02-00

Product Type:3300 5mm Proximity Probe

Origin:USA

Total Length:1 meter

Weight:0.323 kg

Views:124

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330173-08-18-10-02-00 3300 5mm Proximity Probe is part of the industry-proven 3300 series proximity transducers, designed for highly reliable machinery condition monitoring and protection systems. This model features a 5 mm probe tip, a 1.0 meter total length, and rugged coaxial construction, ensuring consistent performance in challenging industrial environments.

The probe operates on eddy-current technology, delivering precise non-contact measurements of shaft vibration and displacement. With its compliance to API 670 standards, it has become a trusted choice in critical applications such as turbines, compressors, and other high-speed rotating machinery. Its stainless-steel housing, electrical isolation, and IP65 protection make it durable for long-term operation in environments with high temperatures, dust, and oil exposure.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330173-08-18-10-02-00 |

| Series | Bently Nevada 3300 Series |

| Probe Type | 5 mm Proximity Probe |

| Tip Diameter | 5 mm |

| Total Length | 1.0 meter |

| Cable Type | Rugged coaxial with shielding |

| Connector Type | Standard coaxial connector |

| Housing Material | Stainless Steel |

| Frequency Response | 0 Hz to 10 kHz |

| Linearity Error | ±1% of full-scale output |

| Operating Temperature | -35°C to +120°C |

| Storage Temperature | -50°C to +150°C |

| Electrical Isolation | Ground-isolated |

| Environmental Rating | IP65 |

| Compliance | API 670, CE, RoHS |

| Weight | 0.323 kg |

Product Applications

The 330173-08-18-10-02-00 is widely used in machinery protection and predictive maintenance systems, including:

Gas and Steam Turbines – Detecting shaft vibration, axial position, and thermal growth.

Compressors – Monitoring imbalance, misalignment, and rotor stability.

Electric Motors and Generators – Ensuring safe operating limits are maintained.

Industrial Pumps – Early detection of bearing degradation and cavitation issues.

Petrochemical and Refining Equipment – Providing continuous monitoring for safety-critical operations.

Heavy-Duty Machinery – Supporting long-term reliability in power plants and manufacturing facilities.

Product Advantages

High Accuracy – ±1% linearity error ensures dependable measurements.

Durable Build – Stainless steel housing and rugged coaxial cable withstand harsh conditions.

Noise Resistance – Shielded design minimizes electromagnetic interference.

Versatile Frequency Range – Suitable for static shaft position and dynamic vibration monitoring.

Full API 670 Compliance – Approved for machine protection systems.

Ground Isolation – Prevents electrical noise coupling into monitoring circuits.

Extended Temperature Tolerance – Operates reliably across a wide thermal range.

Predictive Maintenance Support – Provides critical data for failure prevention strategies.

FAQ

What sensing technology does this probe use?

It uses eddy-current technology to detect shaft displacement and vibration.

Can this probe monitor both static and dynamic signals?

Yes, it can measure static shaft position and dynamic vibration simultaneously.

What is the frequency response capability of this model?

It supports accurate measurements from 0 Hz to 10 kHz.

How does the coaxial shielding improve performance?

It minimizes electromagnetic interference, ensuring clean signal transmission.

Is the probe electrically isolated from the machine shaft?

Yes, it is designed with ground isolation to prevent signal noise.

Does this probe comply with API 670 standards?

Yes, it is fully compliant with API 670 for machinery protection systems.

Can it be used interchangeably with other 330173 series probes?

Yes, but proper matching with proximitor modules and calibration is required.

What types of machinery faults can it help detect?

It can identify imbalance, misalignment, bearing wear, and rotor instability.

How does it maintain accuracy under high temperatures?

It is built with robust materials and insulation rated for extended thermal ranges.

Is this probe compatible with existing Bently Nevada monitoring systems?

Yes, it integrates seamlessly with proximitor sensors and monitoring modules.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...