Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

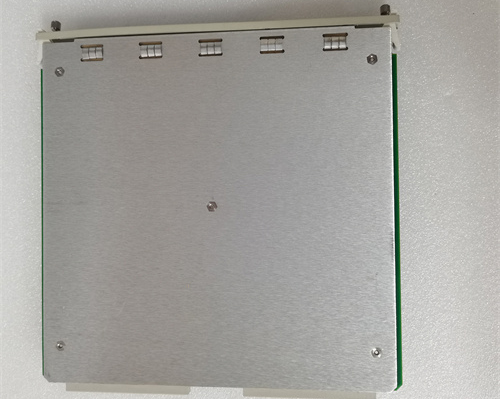

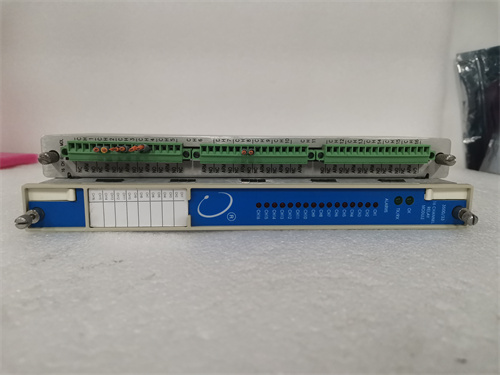

Bently Nevada 330703-000-040-50-02-05 3300 XL 11 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330703-000-040-50-02-05

Product Type:3300 XL 11 mm Proximity Probe

Origin:USA

Total Length:5 m

Weight :0.255 kg

Views:66

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330703-000-040-50-02-05 is high-precision monitoring sensors designed for industrial machinery vibration monitoring and protection. They belong to the Bently Nevada 3300 XL series, a trusted solution in critical rotating machinery monitoring. These models provide reliable and accurate data on vibration levels, allowing operators to detect anomalies, prevent unexpected failures, and optimize maintenance schedules.

Product Advantages

High Accuracy and Sensitivity: Provides precise vibration readings for critical machinery.

Robust Design: Resistant to harsh environmental conditions such as high temperature and moisture.

Quick Response: Real-time monitoring ensures early detection of machinery faults.

Ease of Integration: Compatible with existing Bently Nevada monitoring systems without additional modifications.

Long-Term Reliability: Reduced maintenance requirements with consistent performance over time.

Versatile Applications: Suitable for a wide range of rotating machinery in power, oil & gas, and manufacturing industries.

Technical Specifications

| Parameter | 330703-000-040-50-02-05 |

|---|---|

| Sensor Type | Proximity/Vibration |

| Measurement Range | ±50 mils |

| Output Signal | 4-20 mA / 0-10 V |

| Operating Temperature | -40°C to 120°C |

| Connector Type | 2-pin MIL-C |

| Total Length | 5 m |

| Weight | 0.255 kg |

| Mounting Type | Stud mount |

| Compatible Monitoring System | Bently Nevada 3300 XL |

Product Applications

-

Turbine vibration monitoring and protection

-

Centrifugal pump machinery analysis

-

Compressors and generators monitoring

-

Critical rotating equipment in refineries and petrochemical plants

-

Preventive maintenance programs for industrial machinery

-

Condition-based monitoring in power generation plants

FAQ

Q1: What is the response time of the sensor for sudden vibration spikes?

A1: The sensor responds in less than 2 milliseconds, providing near-instantaneous detection of abnormal vibration.

Q2: Can this sensor operate in high electromagnetic interference (EMI) environments?

A2: Yes, it has EMI-resistant shielding to ensure accurate readings in industrial environments.

Q3: Is the output signal linear across the entire measurement range?

A3: Yes, both models provide a linear output signal across their specified vibration ranges.

Q4: Can the sensor be mounted in any orientation?

A4: The sensor is designed for flexible mounting, but optimal readings are achieved when mounted perpendicular to the monitored shaft.

Q5: Are these sensors compatible with previous Bently Nevada monitoring systems?

A5: Yes, they are backward compatible with most Bently Nevada 3300 XL systems.

Q6: What is the recommended cable type for extending the sensor signal?

A6: Shielded twisted-pair cable is recommended to maintain signal integrity over long distances.

Q7: Does the sensor require calibration before installation?

A7: It is factory-calibrated; however, verification during initial commissioning is recommended.

Q8: How does the sensor handle high-frequency vibration components?

A8: The sensor can capture high-frequency components up to 20 kHz, depending on system configuration.

Q9: Can the sensor output be interfaced with third-party monitoring systems?

A9: Yes, using the standard 4-20 mA or 0-10 V output, it can be integrated with other compatible systems.

Q10: What environmental conditions can these sensors withstand?

A10: They are designed to operate reliably in temperatures from -40°C to 120°C and are resistant to moisture, dust, and industrial contaminants.

Bently Nevada 330703-000-040-50-02-05 3300 XL 11 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330703-000-040-50-02-05

Product Type:3300 XL 11 mm Proximity Probe

Origin:USA

Total Length:5 m

Weight :0.255 kg

Views:66

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330703-000-040-50-02-05 is high-precision monitoring sensors designed for industrial machinery vibration monitoring and protection. They belong to the Bently Nevada 3300 XL series, a trusted solution in critical rotating machinery monitoring. These models provide reliable and accurate data on vibration levels, allowing operators to detect anomalies, prevent unexpected failures, and optimize maintenance schedules.

Product Advantages

High Accuracy and Sensitivity: Provides precise vibration readings for critical machinery.

Robust Design: Resistant to harsh environmental conditions such as high temperature and moisture.

Quick Response: Real-time monitoring ensures early detection of machinery faults.

Ease of Integration: Compatible with existing Bently Nevada monitoring systems without additional modifications.

Long-Term Reliability: Reduced maintenance requirements with consistent performance over time.

Versatile Applications: Suitable for a wide range of rotating machinery in power, oil & gas, and manufacturing industries.

Technical Specifications

| Parameter | 330703-000-040-50-02-05 |

|---|---|

| Sensor Type | Proximity/Vibration |

| Measurement Range | ±50 mils |

| Output Signal | 4-20 mA / 0-10 V |

| Operating Temperature | -40°C to 120°C |

| Connector Type | 2-pin MIL-C |

| Total Length | 5 m |

| Weight | 0.255 kg |

| Mounting Type | Stud mount |

| Compatible Monitoring System | Bently Nevada 3300 XL |

Product Applications

-

Turbine vibration monitoring and protection

-

Centrifugal pump machinery analysis

-

Compressors and generators monitoring

-

Critical rotating equipment in refineries and petrochemical plants

-

Preventive maintenance programs for industrial machinery

-

Condition-based monitoring in power generation plants

FAQ

Q1: What is the response time of the sensor for sudden vibration spikes?

A1: The sensor responds in less than 2 milliseconds, providing near-instantaneous detection of abnormal vibration.

Q2: Can this sensor operate in high electromagnetic interference (EMI) environments?

A2: Yes, it has EMI-resistant shielding to ensure accurate readings in industrial environments.

Q3: Is the output signal linear across the entire measurement range?

A3: Yes, both models provide a linear output signal across their specified vibration ranges.

Q4: Can the sensor be mounted in any orientation?

A4: The sensor is designed for flexible mounting, but optimal readings are achieved when mounted perpendicular to the monitored shaft.

Q5: Are these sensors compatible with previous Bently Nevada monitoring systems?

A5: Yes, they are backward compatible with most Bently Nevada 3300 XL systems.

Q6: What is the recommended cable type for extending the sensor signal?

A6: Shielded twisted-pair cable is recommended to maintain signal integrity over long distances.

Q7: Does the sensor require calibration before installation?

A7: It is factory-calibrated; however, verification during initial commissioning is recommended.

Q8: How does the sensor handle high-frequency vibration components?

A8: The sensor can capture high-frequency components up to 20 kHz, depending on system configuration.

Q9: Can the sensor output be interfaced with third-party monitoring systems?

A9: Yes, using the standard 4-20 mA or 0-10 V output, it can be integrated with other compatible systems.

Q10: What environmental conditions can these sensors withstand?

A10: They are designed to operate reliably in temperatures from -40°C to 120°C and are resistant to moisture, dust, and industrial contaminants.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...