Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

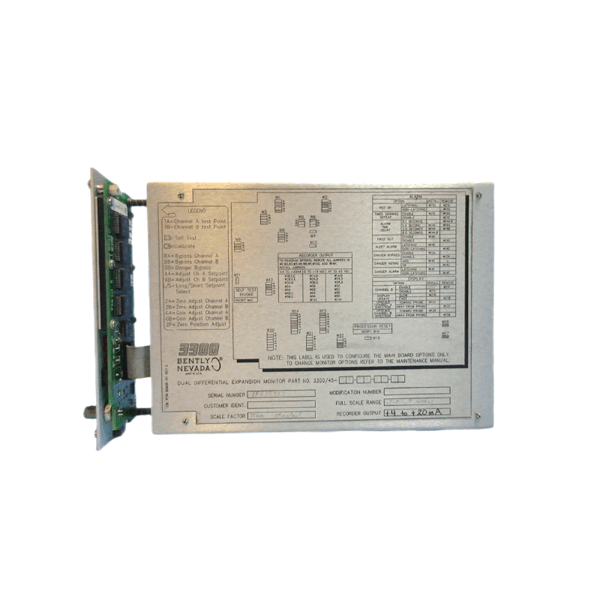

Bently Nevada 3300/45 Dual Differential Expansion Monitor

Manufacturer:Bently Nevada

Product Number:3300/45

Product Type:Dual Differential Expansion Monitor

Origin:USA

Vertical Dimension:83 mm

Weight:1 kg

Views:71

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300/45 Dual Differential Expansion Monitor is a high-performance monitoring system designed for the measurement of differential expansion in machines, such as turbomachinery. It is part of the renowned Bently Nevada 3300 Series, known for its precision and reliability in monitoring the health of critical rotating machinery.

This monitor is designed to measure the differential expansion between two points on a machine’s shaft and casing, ensuring that the equipment operates within its optimal parameters. The 3300/45 is ideal for use in industries where the safety and reliability of rotating machinery are paramount, including power generation, oil and gas, and chemical processing.

With its robust design and advanced features, the 3300/45 is capable of handling demanding industrial environments. It provides real-time data, allowing operators to make informed decisions about machine performance, identify potential problems before they escalate, and optimize maintenance schedules.

Product Specifications

| Specification | Details |

|---|---|

| Model Number | 3300/45 |

| Product Type | Dual Differential Expansion Monitor |

| Measurement Type | Differential Expansion |

| Input Type | Differential Expansion Transducers |

| Input Signal | 4-20 mA output from each sensor |

| Channels | 2 channels (Dual Channel Measurement) |

| Output | 4-20 mA (two analog output channels) |

| Power Supply | 24 V DC |

| Operating Temperature Range | -40°C to +70°C |

| Storage Temperature Range | -40°C to +85°C |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

| Response Time | < 100 ms |

| Certification | CE, UL, RoHS, ATEX (optional) |

| Mounting | Wall or panel mounting |

| Protection Features | Overvoltage, short-circuit, reverse polarity protection |

| Display Type | LCD (optional) |

Applications

The Bently Nevada 3300/45 Dual Differential Expansion Monitor is primarily used in industries with critical rotating machinery. Its primary applications include:

Turbomachinery Monitoring: The module is essential in monitoring steam and gas turbines, compressors, and other critical turbomachinery used in power plants, refineries, and petrochemical facilities.

Power Generation: It is widely used in power generation plants to monitor the differential expansion between the rotating shaft and casing of turbines to avoid equipment failures.

Oil and Gas: The module is employed in gas and oil drilling operations to ensure the continuous, safe operation of drilling rigs, pumps, and compressors.

Refining: Used in refining and chemical plants to monitor the health of critical machinery such as pumps, motors, and compressors.

Industrial Automation: The module integrates with monitoring systems in large-scale industrial automation setups to ensure the integrity of rotating machines.

Critical Process Systems: Used in industries where unplanned downtime can have severe financial and safety consequences, such as pharmaceuticals and food processing.

Rotating Equipment Health Monitoring: The 3300/45 is part of comprehensive condition monitoring systems that keep track of various parameters of rotating equipment, including shaft alignment, vibration, and expansion.

Product Advantages

High Precision: The 3300/45 provides highly accurate differential expansion measurements, essential for preventing shaft or casing damage and ensuring long equipment life.

Real-Time Data: With continuous real-time monitoring, operators are able to respond promptly to changes in machine conditions, preventing potential catastrophic failures.

Advanced Protection Features: Includes overvoltage, short-circuit, and reverse polarity protections, making it a reliable and durable solution in harsh industrial environments.

Wide Operating Temperature Range: The 3300/45 can operate in extreme temperatures ranging from -40°C to +70°C, making it suitable for a wide range of industrial environments.

Easy Integration: It integrates seamlessly with other Bently Nevada systems and third-party monitoring systems, providing a comprehensive solution for machinery health management.

Compact and Lightweight: Its compact size and light weight design (1 kg) make it easy to install and space-efficient.

Improved Maintenance Scheduling: By providing continuous monitoring and early warning of potential problems, the 3300/45 helps to optimize maintenance schedules and reduce downtime.

Durable Design: Built to withstand harsh industrial environments, the 3300/45 is highly reliable, even in challenging conditions such as vibration, dust, and moisture.

Certifications for Safety: The 3300/45 comes with CE, UL, and RoHS certifications, ensuring it meets global safety and environmental standards.

Optional LCD Display: The optional LCD display offers easy access to real-time data and system diagnostics, improving operational efficiency.

FAQ

What does the Bently Nevada 3300/45 measure?

-

The 3300/45 measures the differential expansion between a machine’s rotating shaft and casing, which is critical for the safe operation of turbomachinery.

-

How many channels does the 3300/45 monitor?

-

It features dual channels, allowing for the simultaneous monitoring of two separate differential expansion points.

-

What output does the 3300/45 provide?

-

The 3300/45 provides a 4-20 mA output for each channel, which can be used for further processing or connected to monitoring systems.

-

What is the power supply requirement for the 3300/45?

-

The module requires a 24 V DC power supply for operation.

-

Is the Bently Nevada 3300/45 suitable for outdoor use?

-

Yes, with its wide operating temperature range of -40°C to +70°C, the module is suitable for various industrial environments, including outdoor applications.

-

What certifications does the 3300/45 have?

-

The 3300/45 is CE, UL, and RoHS certified, ensuring it meets safety and environmental standards.

-

Can the 3300/45 be integrated with other Bently Nevada systems?

-

Yes, it integrates seamlessly with other Bently Nevada systems, enabling comprehensive machinery condition monitoring.

-

What is the size of the 3300/45 module?

-

The vertical dimension of the module are 83 mm, making it compact and suitable for various installations.

-

How does the 3300/45 help with maintenance scheduling?

-

By providing real-time monitoring of differential expansion, the 3300/45 allows operators to identify issues early and optimize maintenance schedules to reduce downtime.

-

Can the 3300/45 monitor both small and large machines?

-

Yes, the 3300/45 is versatile and can monitor a wide range of machines, from small turbines to large-scale industrial equipment.

-

Bently Nevada 3300/45 Dual Differential Expansion Monitor

Manufacturer:Bently Nevada

Product Number:3300/45

Product Type:Dual Differential Expansion Monitor

Origin:USA

Vertical Dimension:83 mm

Weight:1 kg

Views:71

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300/45 Dual Differential Expansion Monitor is a high-performance monitoring system designed for the measurement of differential expansion in machines, such as turbomachinery. It is part of the renowned Bently Nevada 3300 Series, known for its precision and reliability in monitoring the health of critical rotating machinery.

This monitor is designed to measure the differential expansion between two points on a machine’s shaft and casing, ensuring that the equipment operates within its optimal parameters. The 3300/45 is ideal for use in industries where the safety and reliability of rotating machinery are paramount, including power generation, oil and gas, and chemical processing.

With its robust design and advanced features, the 3300/45 is capable of handling demanding industrial environments. It provides real-time data, allowing operators to make informed decisions about machine performance, identify potential problems before they escalate, and optimize maintenance schedules.

Product Specifications

| Specification | Details |

|---|---|

| Model Number | 3300/45 |

| Product Type | Dual Differential Expansion Monitor |

| Measurement Type | Differential Expansion |

| Input Type | Differential Expansion Transducers |

| Input Signal | 4-20 mA output from each sensor |

| Channels | 2 channels (Dual Channel Measurement) |

| Output | 4-20 mA (two analog output channels) |

| Power Supply | 24 V DC |

| Operating Temperature Range | -40°C to +70°C |

| Storage Temperature Range | -40°C to +85°C |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

| Response Time | < 100 ms |

| Certification | CE, UL, RoHS, ATEX (optional) |

| Mounting | Wall or panel mounting |

| Protection Features | Overvoltage, short-circuit, reverse polarity protection |

| Display Type | LCD (optional) |

Applications

The Bently Nevada 3300/45 Dual Differential Expansion Monitor is primarily used in industries with critical rotating machinery. Its primary applications include:

Turbomachinery Monitoring: The module is essential in monitoring steam and gas turbines, compressors, and other critical turbomachinery used in power plants, refineries, and petrochemical facilities.

Power Generation: It is widely used in power generation plants to monitor the differential expansion between the rotating shaft and casing of turbines to avoid equipment failures.

Oil and Gas: The module is employed in gas and oil drilling operations to ensure the continuous, safe operation of drilling rigs, pumps, and compressors.

Refining: Used in refining and chemical plants to monitor the health of critical machinery such as pumps, motors, and compressors.

Industrial Automation: The module integrates with monitoring systems in large-scale industrial automation setups to ensure the integrity of rotating machines.

Critical Process Systems: Used in industries where unplanned downtime can have severe financial and safety consequences, such as pharmaceuticals and food processing.

Rotating Equipment Health Monitoring: The 3300/45 is part of comprehensive condition monitoring systems that keep track of various parameters of rotating equipment, including shaft alignment, vibration, and expansion.

Product Advantages

High Precision: The 3300/45 provides highly accurate differential expansion measurements, essential for preventing shaft or casing damage and ensuring long equipment life.

Real-Time Data: With continuous real-time monitoring, operators are able to respond promptly to changes in machine conditions, preventing potential catastrophic failures.

Advanced Protection Features: Includes overvoltage, short-circuit, and reverse polarity protections, making it a reliable and durable solution in harsh industrial environments.

Wide Operating Temperature Range: The 3300/45 can operate in extreme temperatures ranging from -40°C to +70°C, making it suitable for a wide range of industrial environments.

Easy Integration: It integrates seamlessly with other Bently Nevada systems and third-party monitoring systems, providing a comprehensive solution for machinery health management.

Compact and Lightweight: Its compact size and light weight design (1 kg) make it easy to install and space-efficient.

Improved Maintenance Scheduling: By providing continuous monitoring and early warning of potential problems, the 3300/45 helps to optimize maintenance schedules and reduce downtime.

Durable Design: Built to withstand harsh industrial environments, the 3300/45 is highly reliable, even in challenging conditions such as vibration, dust, and moisture.

Certifications for Safety: The 3300/45 comes with CE, UL, and RoHS certifications, ensuring it meets global safety and environmental standards.

Optional LCD Display: The optional LCD display offers easy access to real-time data and system diagnostics, improving operational efficiency.

FAQ

What does the Bently Nevada 3300/45 measure?

-

The 3300/45 measures the differential expansion between a machine’s rotating shaft and casing, which is critical for the safe operation of turbomachinery.

-

How many channels does the 3300/45 monitor?

-

It features dual channels, allowing for the simultaneous monitoring of two separate differential expansion points.

-

What output does the 3300/45 provide?

-

The 3300/45 provides a 4-20 mA output for each channel, which can be used for further processing or connected to monitoring systems.

-

What is the power supply requirement for the 3300/45?

-

The module requires a 24 V DC power supply for operation.

-

Is the Bently Nevada 3300/45 suitable for outdoor use?

-

Yes, with its wide operating temperature range of -40°C to +70°C, the module is suitable for various industrial environments, including outdoor applications.

-

What certifications does the 3300/45 have?

-

The 3300/45 is CE, UL, and RoHS certified, ensuring it meets safety and environmental standards.

-

Can the 3300/45 be integrated with other Bently Nevada systems?

-

Yes, it integrates seamlessly with other Bently Nevada systems, enabling comprehensive machinery condition monitoring.

-

What is the size of the 3300/45 module?

-

The vertical dimension of the module are 83 mm, making it compact and suitable for various installations.

-

How does the 3300/45 help with maintenance scheduling?

-

By providing real-time monitoring of differential expansion, the 3300/45 allows operators to identify issues early and optimize maintenance schedules to reduce downtime.

-

Can the 3300/45 monitor both small and large machines?

-

Yes, the 3300/45 is versatile and can monitor a wide range of machines, from small turbines to large-scale industrial equipment.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...