TSI (Turbine Supervisory Instrumentation) is an important technology widely used in industrial fields, particularly for monitoring turbines and rotating equipment. It primarily serves to detect and monitor the condition and performance of machinery, ensuring the safety, stability, and efficient operation of equipment. Eddy current sensor technology is a core component of TSI systems, helping companies perform preventive maintenance through real-time data, preventing potential equipment failures, reducing downtime, and extending the lifespan of machinery.

What is a TSI System

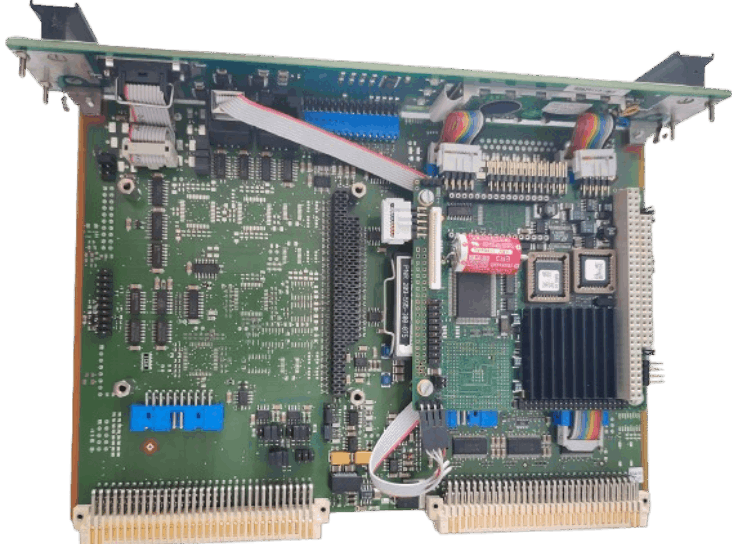

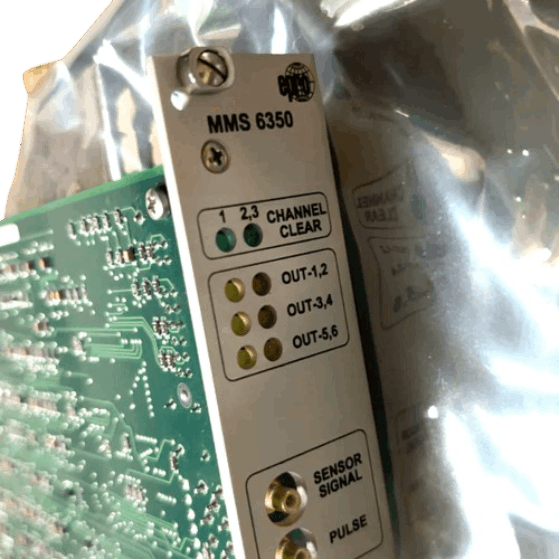

A TSI system is a monitoring and diagnostic system specifically designed for rotating machinery, commonly used in large turbine units in power plants, the oil and gas industry, chemical plants, and other industrial sectors. During operation, these machines undergo changes in vibration, temperature, and pressure. The TSI system collects real-time data from multiple sensors (such as eddy current sensors, accelerometers, and temperature sensors) and analyzes the operational status of the equipment.

By monitoring key parameters like shaft vibration, shaft displacement, and speed, TSI systems can detect anomalies such as bearing wear, rotor imbalance, and mechanical looseness, enabling preventive maintenance and preventing major breakdowns.

How TSI Works

TSI systems rely on various sensors and monitoring devices to detect the parameters of rotating machinery. Below are some of the key monitored parameters and their functions:

Shaft Vibration Monitoring: The vibration of the shaft is a critical indicator of the health of the equipment, especially in high-speed rotating turbine units. Shaft vibration monitoring helps detect issues like rotor imbalance or mechanical looseness.

Shaft Displacement Monitoring: Shaft displacement sensors can detect the relative displacement of the shaft center, which is crucial for identifying problems like bearing wear or misalignment.

Speed Monitoring: The speed of turbine units is a key factor for their operational efficiency and safety. The TSI system measures and controls the speed to ensure the equipment operates under optimal conditions.

Temperature and Pressure Monitoring: TSI systems also monitor the temperature and pressure of the turbine unit to ensure it operates within safe limits, avoiding failures due to overheating or overpressure.

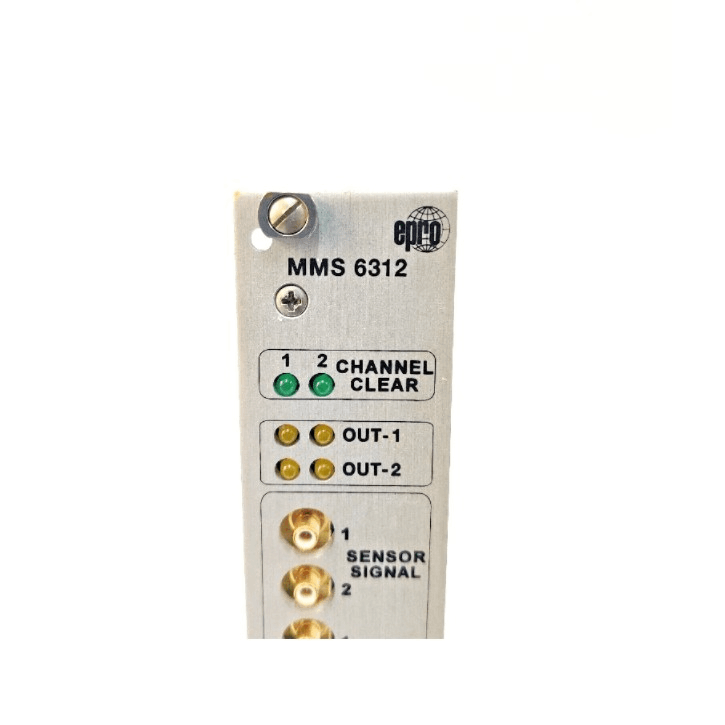

The Application of Eddy Current Sensors in TSI

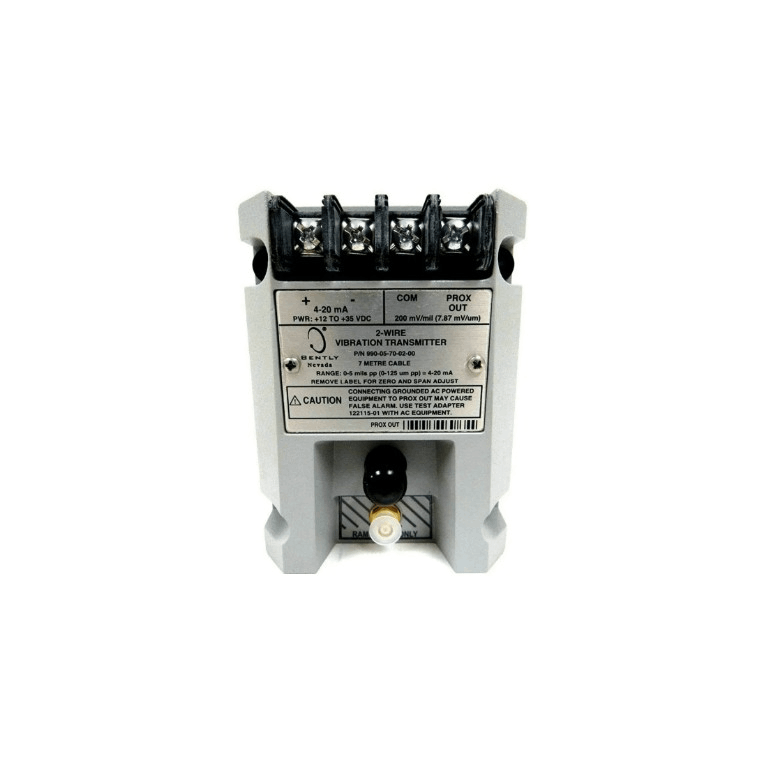

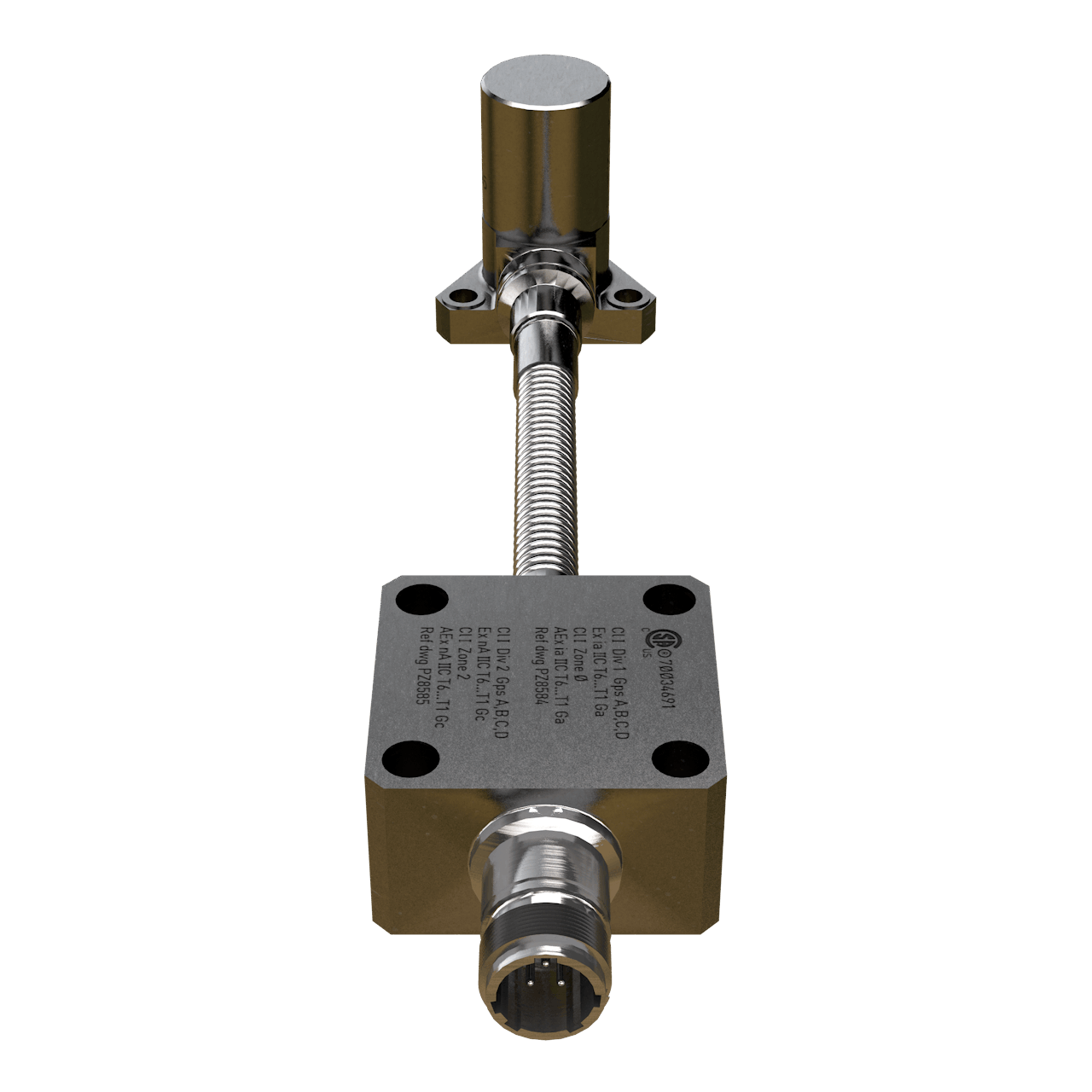

Eddy current sensors are one of the most commonly used sensors in TSI systems, particularly for non-contact monitoring of rotating equipment. Eddy current sensors detect the slight displacement and vibration of monitored objects, such as shafts or bearings, providing real-time monitoring of the health status of rotating machinery. Their primary working principle is based on electromagnetic induction. When the sensor probe approaches a conductive object, it generates eddy currents on the surface of the object, and changes in these currents reflect the object’s displacement or vibration.

Advantages of Eddy Current Sensors

Non-contact Measurement: Eddy current sensors can monitor equipment accurately without contacting it, avoiding wear on the surface of the equipment.

High Precision and Fast Response: Eddy current sensors can capture small changes in rotating machinery in real-time, providing high-precision data.

Suitability for Extreme Environments: Eddy current sensors can operate normally in high-temperature, high-pressure, or harsh environments, making them ideal for industrial applications.

Application Scenarios of Eddy Current Sensors

Eddy current sensors are widely used in heavy industries such as power plants, petrochemical equipment, and steel metallurgy. They are mainly used for monitoring the shaft vibration and shaft displacement of turbines, compressors, generators, and other equipment. Failures in these devices can lead to significant economic losses, so the application of eddy current sensors in TSI systems helps companies detect potential issues early and avoid major accidents.

The Industry Significance of TSI Systems

In modern industries, the reliability and safety of rotating machinery are of utmost importance. TSI systems bring significant benefits to industrial enterprises through real-time equipment monitoring:

Improved Safety: TSI systems can detect potential issues during equipment operation in advance, preventing safety incidents caused by equipment failures. This is especially crucial in high-risk industries such as oil, gas, and chemicals.

Reduced Downtime: Equipment failures can cause production stoppages, leading to huge economic losses. Through preventive maintenance facilitated by TSI systems, companies can significantly reduce downtime and improve production efficiency.

Extended Equipment Lifespan: TSI systems monitor the health status of equipment in real-time, enabling companies to identify wear and aging issues and conduct targeted maintenance, thereby extending the life of the equipment.

Lower Maintenance Costs: Compared to reactive repairs, TSI systems allow companies to perform maintenance before failures occur, avoiding large-scale equipment damage and reducing maintenance costs.

Future Prospects

With the continuous development of industrial automation and intelligence, the application of TSI systems will become even more widespread and in-depth. Future TSI systems will integrate with big data, artificial intelligence, and other technologies, achieving smarter equipment monitoring and fault prediction. With more accurate data analysis and prediction, TSI systems can help companies take action before equipment failures occur, further enhancing production efficiency and safety.

Conclusion

TSI systems are vital tools in modern industries for ensuring the safety of rotating equipment and improving production efficiency, especially in monitoring turbines, compressors, and similar equipment. Eddy current sensors, as a crucial component of TSI systems, are widely applied in industrial fields due to their non-contact, high-precision, and extreme-environment adaptation characteristics. In the future, as technology advances, TSI systems will continue to play a key role in industrial monitoring and equipment maintenance, providing more reliable and efficient solutions for enterprises.