Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

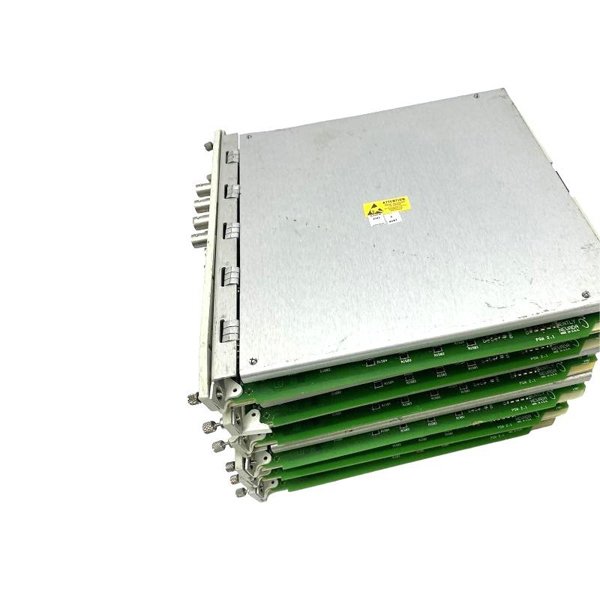

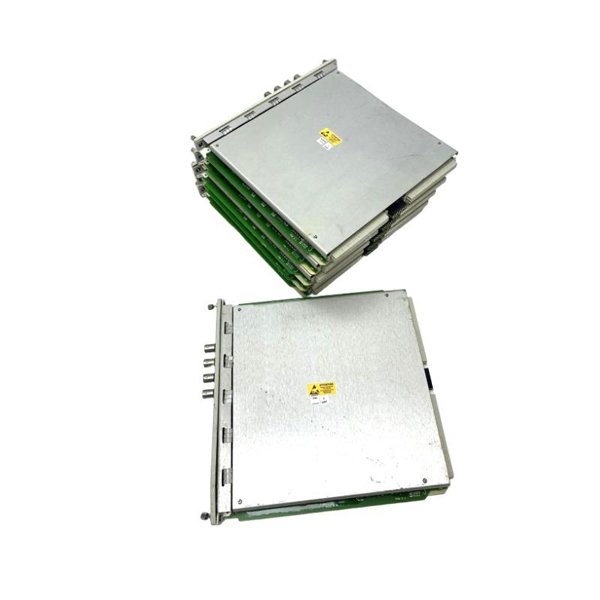

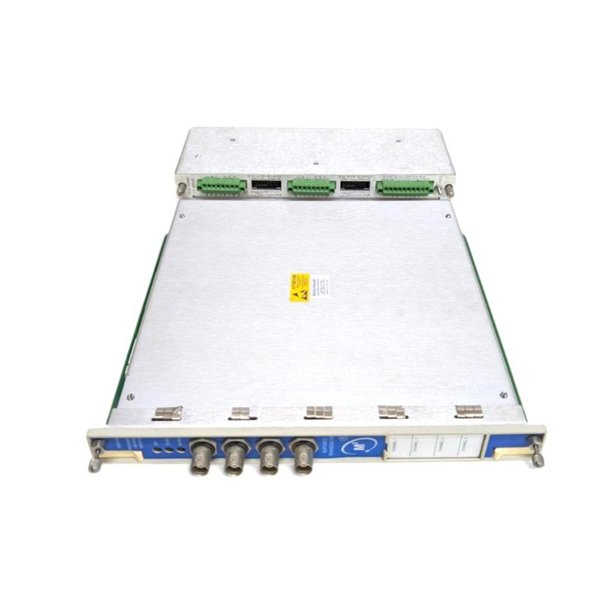

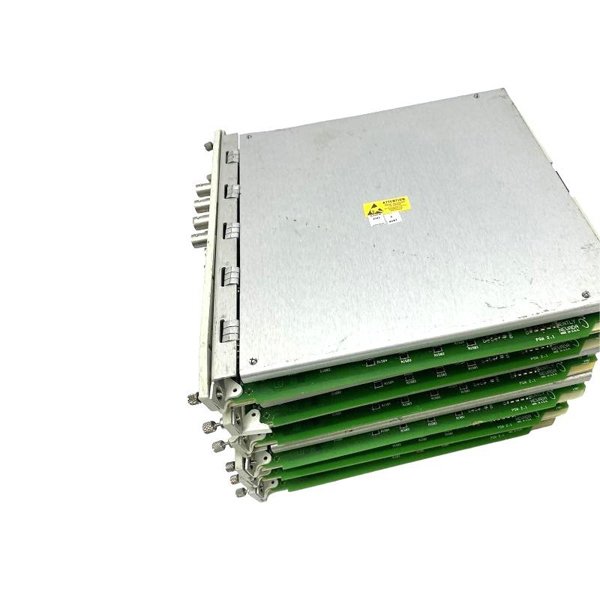

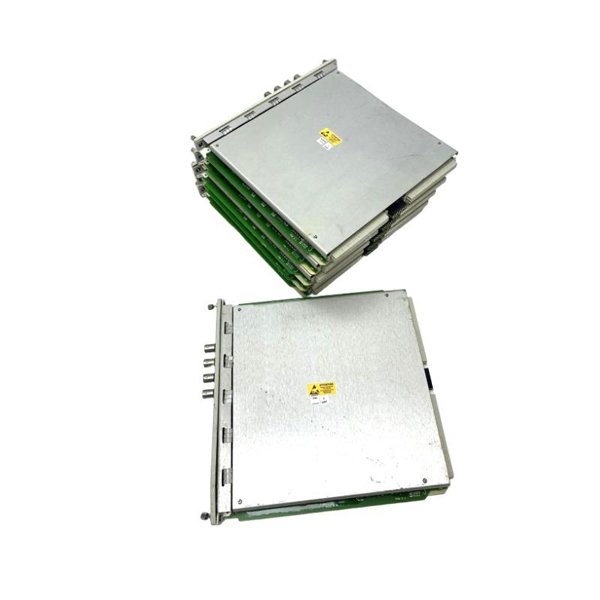

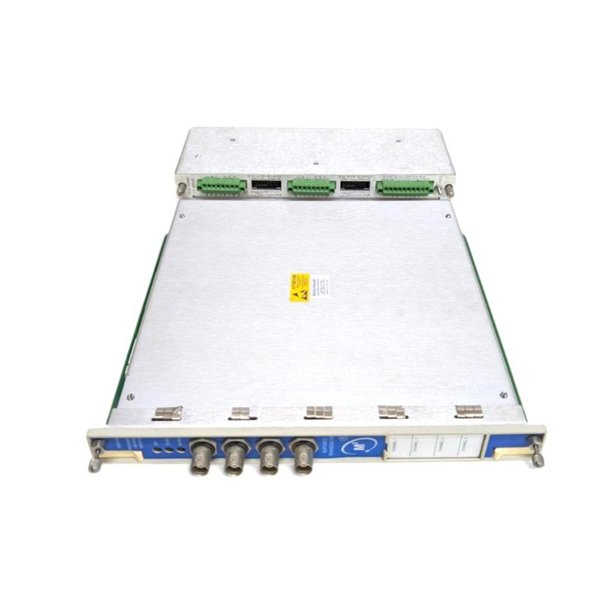

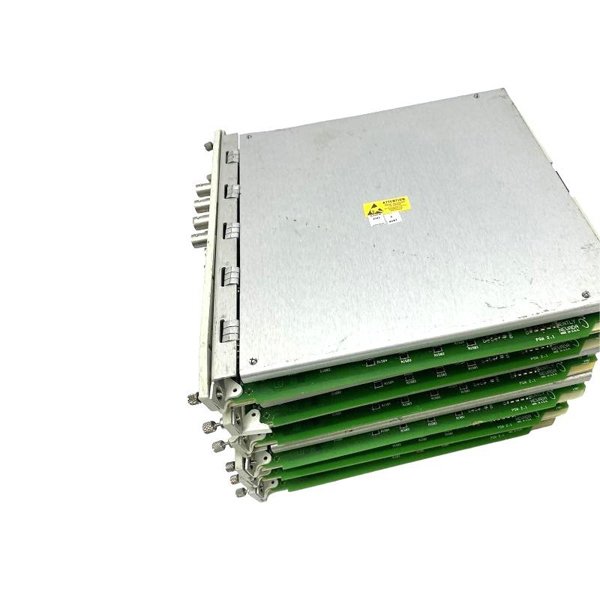

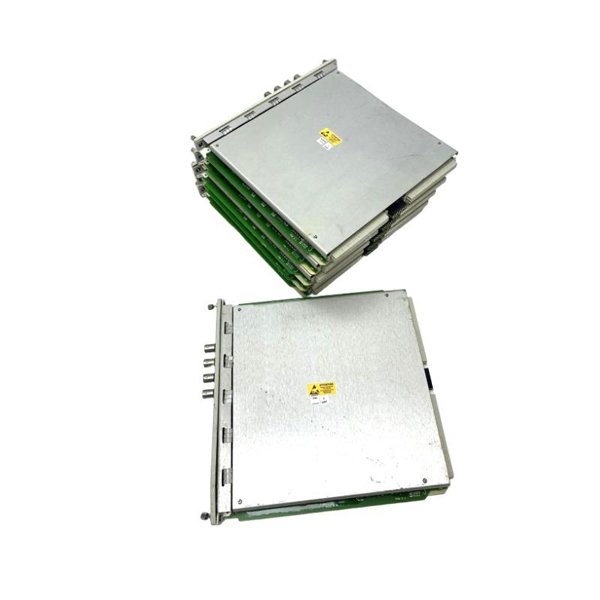

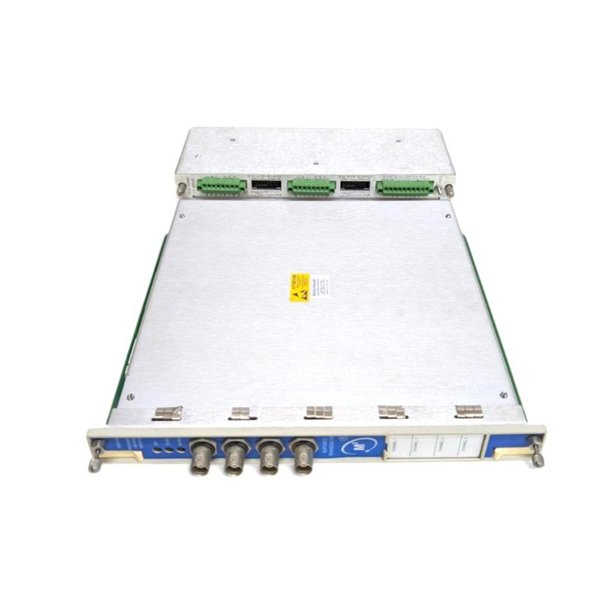

Bently Nevada 3500/42-06-00 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-06-00

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:33

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-06-00 Proximitor Seismic Monitor is a high-performance monitoring module designed for critical vibration and position measurements in industrial rotating machinery. It provides continuous surveillance of shaft vibration, position, and phase reference signals, enabling predictive maintenance and operational safety in demanding environments.

Product Specifications

| Parameter | Value |

|---|---|

| Model | 3500/42-06-00 |

| Measurement Type | Proximitor Seismic |

| Input Channels | 2 |

| Frequency Response | 4 Hz to 60 kHz |

| Power Supply | From 3500 Rack Backplane |

| Output Signal | 4-20 mA proportional to measurement |

| Communication | System Configuration via 3500 Rack |

| Dimensions (H x W x D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Mounting | 3500 Series Rack |

| Operating Temperature | -30°C to +65°C |

| Compliance | CE, CSA, ATEX, IECEx |

Applications

Turbomachinery Monitoring: Detects shaft vibration and displacement in turbines, compressors, and pumps.

Seismic Event Detection: Monitors low-frequency vibration from foundation or structural movement.

Critical Asset Protection: Ensures machinery protection by triggering alarms and shutdown sequences.

Condition-Based Maintenance: Integrates with plant control systems for predictive diagnostics.

Advantages

High Accuracy: Delivers precise measurements with minimal drift over time.

Modular Integration: Fits seamlessly into the 3500 Series Monitoring System.

Dual-Channel Design: Provides simultaneous monitoring for multiple parameters.

Comprehensive Diagnostics: Detects sensor and wiring faults for reliability.

Wide Environmental Tolerance: Operates reliably in harsh industrial conditions.

FAQ

Q: What types of sensors are compatible?

A: Proximity probes, velocity transducers, and accelerometers designed for 3500 Series systems.

Q: Can it monitor both radial and axial vibration?

A: Yes, it supports multiple vibration and position measurement configurations.

Q: How is it configured?

A: Through the 3500 rack using the System Configuration Software.

Q: What is the update rate for measurements?

A: Measurements are updated in milliseconds for real-time monitoring.

Q: Does it support redundant configurations?

A: Yes, dual modules can be used for redundancy.

Q: Can it trigger machine shutdown?

A: Yes, via relay modules integrated into the 3500 system.

Q: What certifications does it have?

A: CE, CSA, ATEX, and IECEx.

Q: Is field calibration required?

A: It is factory calibrated; periodic verification is recommended.

Q: Can it store historical data?

A: Historical trending is handled through the 3500 System and connected software.

Q: What industries use it most?

A: Oil & gas, power generation, petrochemical, and heavy manufacturing.

Bently Nevada 3500/42-06-00 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-06-00

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:33

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-06-00 Proximitor Seismic Monitor is a high-performance monitoring module designed for critical vibration and position measurements in industrial rotating machinery. It provides continuous surveillance of shaft vibration, position, and phase reference signals, enabling predictive maintenance and operational safety in demanding environments.

Product Specifications

| Parameter | Value |

|---|---|

| Model | 3500/42-06-00 |

| Measurement Type | Proximitor Seismic |

| Input Channels | 2 |

| Frequency Response | 4 Hz to 60 kHz |

| Power Supply | From 3500 Rack Backplane |

| Output Signal | 4-20 mA proportional to measurement |

| Communication | System Configuration via 3500 Rack |

| Dimensions (H x W x D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Mounting | 3500 Series Rack |

| Operating Temperature | -30°C to +65°C |

| Compliance | CE, CSA, ATEX, IECEx |

Applications

Turbomachinery Monitoring: Detects shaft vibration and displacement in turbines, compressors, and pumps.

Seismic Event Detection: Monitors low-frequency vibration from foundation or structural movement.

Critical Asset Protection: Ensures machinery protection by triggering alarms and shutdown sequences.

Condition-Based Maintenance: Integrates with plant control systems for predictive diagnostics.

Advantages

High Accuracy: Delivers precise measurements with minimal drift over time.

Modular Integration: Fits seamlessly into the 3500 Series Monitoring System.

Dual-Channel Design: Provides simultaneous monitoring for multiple parameters.

Comprehensive Diagnostics: Detects sensor and wiring faults for reliability.

Wide Environmental Tolerance: Operates reliably in harsh industrial conditions.

FAQ

Q: What types of sensors are compatible?

A: Proximity probes, velocity transducers, and accelerometers designed for 3500 Series systems.

Q: Can it monitor both radial and axial vibration?

A: Yes, it supports multiple vibration and position measurement configurations.

Q: How is it configured?

A: Through the 3500 rack using the System Configuration Software.

Q: What is the update rate for measurements?

A: Measurements are updated in milliseconds for real-time monitoring.

Q: Does it support redundant configurations?

A: Yes, dual modules can be used for redundancy.

Q: Can it trigger machine shutdown?

A: Yes, via relay modules integrated into the 3500 system.

Q: What certifications does it have?

A: CE, CSA, ATEX, and IECEx.

Q: Is field calibration required?

A: It is factory calibrated; periodic verification is recommended.

Q: Can it store historical data?

A: Historical trending is handled through the 3500 System and connected software.

Q: What industries use it most?

A: Oil & gas, power generation, petrochemical, and heavy manufacturing.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...