Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

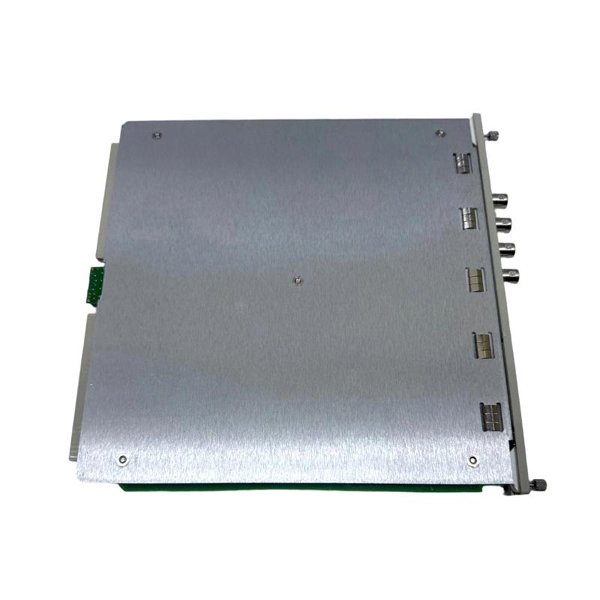

Bently Nevada 3500/72 176449-08+135489-01 Recip Rod Position Monitor

Manufacturer:Bently Nevada

Product Number:3500/72 176449-08+135489-01

Product Type:Recip Rod Position Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:57

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/72 176449-08+135489-01 Recip Rod Position Monitor is a high-precision monitoring module designed for reciprocating machinery such as compressors and pumps. As part of the 3500 Series Machinery Protection System, it provides real-time measurements of rod positions to protect machinery from overtravel, misalignment, and abnormal operation conditions.

The module works with proximity probes or displacement sensors to continuously track rod motion. Data collected is used to trigger alarms, support predictive maintenance, and provide operators with insights for optimal machine performance. Integration with other 3500 Series modules ensures centralized system management, diagnostics, and operational reliability.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Bently Nevada 3500/72 176449-08+135489-01 |

| Product Type | Recip Rod Position Monitor |

| Input Type | Proximity probe or displacement sensor |

| Number of Channels | 1-channel standard (expandable with multiple modules) |

| Measurement Range | ±50 mm typical (sensor-dependent) |

| Frequency Response | DC to 1 kHz |

| Alarm Capability | Rod overtravel, high/low limits, windowed alarms |

| Signal Isolation | Full galvanic isolation for input and output circuits |

| Accuracy | ±0.25% of full scale |

| Response Time | <20 ms |

| Communication | 3500 Series backplane interface |

| Power Supply | 24 VDC nominal |

| Operating Temperature | 0 to 60 °C |

| Storage Temperature | -20 to 70 °C |

| Relative Humidity | 5% to 95% non-condensing |

| Compliance | CE, UL, CSA |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Product Applications

The 3500/72 Recip Rod Position Monitor is suitable for a variety of industrial applications where accurate rod position measurement is essential:

Oil & Gas – Monitoring reciprocating compressors in pipelines and refinery operations.

Petrochemical Industry – Rod motion detection in pumps and process compressors.

Power Generation – Auxiliary reciprocating pump and compressor rod monitoring.

Chemical Processing – Detecting abnormal rod movement and preventing overtravel.

Marine & Offshore – Shipboard reciprocating machinery monitoring for operational safety.

Industrial Manufacturing – Ensuring rod travel limits to prevent mechanical damage.

Product Advantages

High Measurement Accuracy – ±0.25% full-scale ensures reliable rod position readings.

Fast Response – Less than 20 ms response time allows immediate detection of abnormal motion.

Wide Frequency Range – DC to 1 kHz accommodates slow and rapid rod movements.

Fully Isolated Signals – Galvanic isolation protects system integrity and reduces electrical noise effects.

Configurable Alarm Options – Overtravel, high/low limit, and windowed alarms enhance machinery protection.

Seamless 3500 Series Integration – Compatible with the 3500 Series for centralized monitoring and diagnostics.

Rugged Industrial Design – Reliable operation in harsh environments and electrically noisy conditions.

Self-Diagnostic Capabilities – Provides module status and fault detection for preventive maintenance.

FAQ

Which sensor types are supported by this module?

Proximity probes or displacement sensors.

How many channels does each module provide?

One channel per module; multiple modules can be used for additional points.

What is the measurement range?

±50 mm typical, sensor-dependent.

What frequency range does it support?

DC to 1 kHz.

Does it provide rod overtravel alarms?

Yes, overtravel, high/low limits, and windowed alarms are supported.

Is the input signal isolated from the backplane and other channels?

Yes, full galvanic isolation is provided.

What is the response time for the module?

Less than 20 ms.

What is the accuracy of rod position measurement?

±0.25% of full-scale reading.

Can it integrate with other 3500 Series modules?

Yes, it integrates seamlessly with the 3500 Series system.

Can it operate reliably in electrically noisy industrial environments?

Yes, it is designed for robust operation in harsh industrial conditions.

Bently Nevada 3500/72 176449-08+135489-01 Recip Rod Position Monitor

Manufacturer:Bently Nevada

Product Number:3500/72 176449-08+135489-01

Product Type:Recip Rod Position Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:57

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/72 176449-08+135489-01 Recip Rod Position Monitor is a high-precision monitoring module designed for reciprocating machinery such as compressors and pumps. As part of the 3500 Series Machinery Protection System, it provides real-time measurements of rod positions to protect machinery from overtravel, misalignment, and abnormal operation conditions.

The module works with proximity probes or displacement sensors to continuously track rod motion. Data collected is used to trigger alarms, support predictive maintenance, and provide operators with insights for optimal machine performance. Integration with other 3500 Series modules ensures centralized system management, diagnostics, and operational reliability.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Bently Nevada 3500/72 176449-08+135489-01 |

| Product Type | Recip Rod Position Monitor |

| Input Type | Proximity probe or displacement sensor |

| Number of Channels | 1-channel standard (expandable with multiple modules) |

| Measurement Range | ±50 mm typical (sensor-dependent) |

| Frequency Response | DC to 1 kHz |

| Alarm Capability | Rod overtravel, high/low limits, windowed alarms |

| Signal Isolation | Full galvanic isolation for input and output circuits |

| Accuracy | ±0.25% of full scale |

| Response Time | <20 ms |

| Communication | 3500 Series backplane interface |

| Power Supply | 24 VDC nominal |

| Operating Temperature | 0 to 60 °C |

| Storage Temperature | -20 to 70 °C |

| Relative Humidity | 5% to 95% non-condensing |

| Compliance | CE, UL, CSA |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Product Applications

The 3500/72 Recip Rod Position Monitor is suitable for a variety of industrial applications where accurate rod position measurement is essential:

Oil & Gas – Monitoring reciprocating compressors in pipelines and refinery operations.

Petrochemical Industry – Rod motion detection in pumps and process compressors.

Power Generation – Auxiliary reciprocating pump and compressor rod monitoring.

Chemical Processing – Detecting abnormal rod movement and preventing overtravel.

Marine & Offshore – Shipboard reciprocating machinery monitoring for operational safety.

Industrial Manufacturing – Ensuring rod travel limits to prevent mechanical damage.

Product Advantages

High Measurement Accuracy – ±0.25% full-scale ensures reliable rod position readings.

Fast Response – Less than 20 ms response time allows immediate detection of abnormal motion.

Wide Frequency Range – DC to 1 kHz accommodates slow and rapid rod movements.

Fully Isolated Signals – Galvanic isolation protects system integrity and reduces electrical noise effects.

Configurable Alarm Options – Overtravel, high/low limit, and windowed alarms enhance machinery protection.

Seamless 3500 Series Integration – Compatible with the 3500 Series for centralized monitoring and diagnostics.

Rugged Industrial Design – Reliable operation in harsh environments and electrically noisy conditions.

Self-Diagnostic Capabilities – Provides module status and fault detection for preventive maintenance.

FAQ

Which sensor types are supported by this module?

Proximity probes or displacement sensors.

How many channels does each module provide?

One channel per module; multiple modules can be used for additional points.

What is the measurement range?

±50 mm typical, sensor-dependent.

What frequency range does it support?

DC to 1 kHz.

Does it provide rod overtravel alarms?

Yes, overtravel, high/low limits, and windowed alarms are supported.

Is the input signal isolated from the backplane and other channels?

Yes, full galvanic isolation is provided.

What is the response time for the module?

Less than 20 ms.

What is the accuracy of rod position measurement?

±0.25% of full-scale reading.

Can it integrate with other 3500 Series modules?

Yes, it integrates seamlessly with the 3500 Series system.

Can it operate reliably in electrically noisy industrial environments?

Yes, it is designed for robust operation in harsh industrial conditions.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...