Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

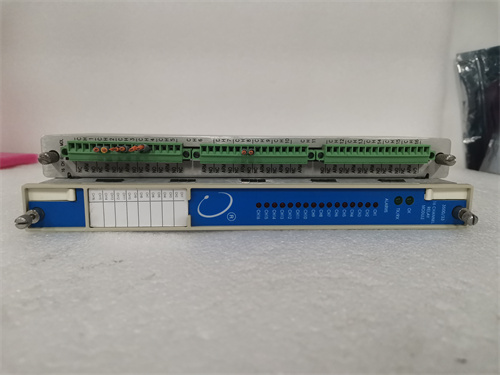

Bently Nevada 330101-00-16-05-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330101-00-16-05-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Dimensions:Total Length : 0.5 meter

Weight:0.161kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

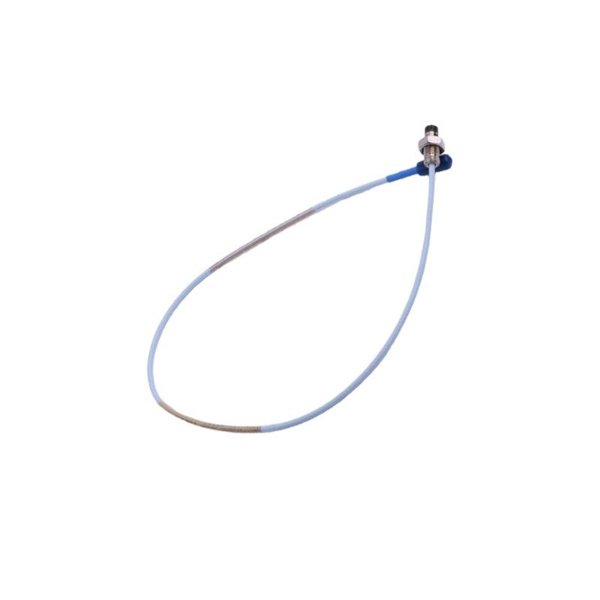

The Bently Nevada 330101-00-16-05-02-05 is a member of the trusted 3300 XL 8 mm Proximity Transducer System, designed for accurate, non-contact measurement of static and dynamic motion in rotating machinery. It forms part of a system comprising a proximity probe, extension cable, and Proximitor® sensor, specifically engineered for continuous monitoring of shaft vibration, axial position, and rotor dynamics.

This model features a 16 ft (4.9 m) total system length, consisting of a 5 ft (1.5 m) proximity probe and an 11 ft (3.4 m) extension cable, offering optimal flexibility in installations where sensor placement and cabling paths must be tailored to machinery configuration.

Key Features

-

8 mm probe tip for general-purpose and critical vibration monitoring

-

Total system length of 16 ft: 5 ft probe + 11 ft extension cable

-

Threaded stainless steel body with PEEK sensing tip for chemical resistance

-

High linearity and precision compliant with API 670 standards

-

Resistant to electromagnetic and radio-frequency interference

-

Compatible with 3300 XL Proximitor sensors

-

Designed for rugged industrial environments including turbines, compressors, and motors

-

IP67 rated for environmental sealing

-

Excellent long-term stability and repeatability

Technical Specifications

| Parameter | Specification |

|---|---|

| Probe Tip Diameter | 8 mm |

| Probe Length | 5 ft (1.5 m) |

| Extension Cable Length | 11 ft (3.4 m) |

| Total System Length | 16 ft (4.9 m) |

| Thread Size | 3/8-24 UNF |

| Connector Type | Coaxial connector with gold-plated contacts |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Linearity | ±0.25% full-scale typical |

| Measurement Range | 2 mm (80 mils) nominal |

| Frequency Response | DC to 10 kHz |

| Operating Temperature | -35°C to +177°C (Probe and Extension Cable) |

| Environmental Rating | IP67 |

| Compliance Standards | API 670, CE, RoHS, ATEX/IECEx (depending on configuration) |

| Materials | Probe: Stainless Steel; Tip: PEEK; Cable Jacket: Polyurethane |

| Dimensions | Total Length : 0.5 meter |

| Weight | 0.161 kg |

Product Advantages

Precise Condition Monitoring: Delivers accurate real-time data for shaft vibration and position analysis.

Flexible Configuration: Mixed probe and cable lengths accommodate complex equipment layouts.

High Durability: Engineered for extreme temperatures, moisture, oil, and vibration.

Compliance Ready: Adheres to API 670 requirements for safety and performance assurance.

Simplified Integration: Compatible with all 3300 XL Proximitor Sensors and Bently Nevada 3500 monitoring systems.

Enhanced Uptime: Aids in detecting mechanical issues before failure, reducing maintenance costs and downtime.

Reliable in Harsh Environments: Maintains performance in areas with high EMI, oil exposure, and thermal variation.

Industry Applications

Steam and Gas Turbines – Shaft vibration, axial thrust, and radial position detection

Compressors and Pumps – Monitor dynamic shaft behavior to prevent catastrophic failure

Generators and Motors – Identify imbalance, misalignment, or looseness

Gearboxes – Track gear mesh conditions and bearing wear

Oil & Gas Refineries – Continuous machine health monitoring in hazardous environments

Power Generation – Part of critical monitoring systems in base-load and peaking power plants

Heavy Machinery – For condition-based maintenance strategies in industrial plants

Frequently Asked Questions (FAQ)

What does the model number 330101-00-16-05-02-05 represent?

It designates a proximity probe system with a total length of 16 ft (5 ft probe + 11 ft extension), with specific connector and thread type.

Can this probe be used in explosive atmospheres?

Certain versions with ATEX/IECEx certifications are suitable for hazardous zones.

What sensor should I pair with this probe?

It is compatible with Bently Nevada 3300 XL Proximitor Sensors for accurate system response.

Does this probe meet API 670 standards?

Yes, it complies fully with API 670 performance and reliability criteria.

What cable materials are used?

The extension cable uses a polyurethane jacket for superior abrasion and chemical resistance.

Is it suitable for high-temperature equipment?

Yes, it supports operating temperatures up to 177°C.

What vibration range does it measure?

The system measures dynamic motion within a 2 mm (80 mils) range with ±0.25% accuracy.

Can I cut or shorten the cable length on-site?

No. The total system length is factory-calibrated and must remain unchanged to ensure accuracy.

Does the probe require periodic calibration?

No field calibration is needed, but it is recommended to follow standard maintenance checks.

What maintenance does this product require?

Routine inspection for physical damage and secure connections is typically sufficient.

Bently Nevada 330101-00-16-05-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330101-00-16-05-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Dimensions:Total Length : 0.5 meter

Weight:0.161kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-16-05-02-05 is a member of the trusted 3300 XL 8 mm Proximity Transducer System, designed for accurate, non-contact measurement of static and dynamic motion in rotating machinery. It forms part of a system comprising a proximity probe, extension cable, and Proximitor® sensor, specifically engineered for continuous monitoring of shaft vibration, axial position, and rotor dynamics.

This model features a 16 ft (4.9 m) total system length, consisting of a 5 ft (1.5 m) proximity probe and an 11 ft (3.4 m) extension cable, offering optimal flexibility in installations where sensor placement and cabling paths must be tailored to machinery configuration.

Key Features

-

8 mm probe tip for general-purpose and critical vibration monitoring

-

Total system length of 16 ft: 5 ft probe + 11 ft extension cable

-

Threaded stainless steel body with PEEK sensing tip for chemical resistance

-

High linearity and precision compliant with API 670 standards

-

Resistant to electromagnetic and radio-frequency interference

-

Compatible with 3300 XL Proximitor sensors

-

Designed for rugged industrial environments including turbines, compressors, and motors

-

IP67 rated for environmental sealing

-

Excellent long-term stability and repeatability

Technical Specifications

| Parameter | Specification |

|---|---|

| Probe Tip Diameter | 8 mm |

| Probe Length | 5 ft (1.5 m) |

| Extension Cable Length | 11 ft (3.4 m) |

| Total System Length | 16 ft (4.9 m) |

| Thread Size | 3/8-24 UNF |

| Connector Type | Coaxial connector with gold-plated contacts |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Linearity | ±0.25% full-scale typical |

| Measurement Range | 2 mm (80 mils) nominal |

| Frequency Response | DC to 10 kHz |

| Operating Temperature | -35°C to +177°C (Probe and Extension Cable) |

| Environmental Rating | IP67 |

| Compliance Standards | API 670, CE, RoHS, ATEX/IECEx (depending on configuration) |

| Materials | Probe: Stainless Steel; Tip: PEEK; Cable Jacket: Polyurethane |

| Dimensions | Total Length : 0.5 meter |

| Weight | 0.161 kg |

Product Advantages

Precise Condition Monitoring: Delivers accurate real-time data for shaft vibration and position analysis.

Flexible Configuration: Mixed probe and cable lengths accommodate complex equipment layouts.

High Durability: Engineered for extreme temperatures, moisture, oil, and vibration.

Compliance Ready: Adheres to API 670 requirements for safety and performance assurance.

Simplified Integration: Compatible with all 3300 XL Proximitor Sensors and Bently Nevada 3500 monitoring systems.

Enhanced Uptime: Aids in detecting mechanical issues before failure, reducing maintenance costs and downtime.

Reliable in Harsh Environments: Maintains performance in areas with high EMI, oil exposure, and thermal variation.

Industry Applications

Steam and Gas Turbines – Shaft vibration, axial thrust, and radial position detection

Compressors and Pumps – Monitor dynamic shaft behavior to prevent catastrophic failure

Generators and Motors – Identify imbalance, misalignment, or looseness

Gearboxes – Track gear mesh conditions and bearing wear

Oil & Gas Refineries – Continuous machine health monitoring in hazardous environments

Power Generation – Part of critical monitoring systems in base-load and peaking power plants

Heavy Machinery – For condition-based maintenance strategies in industrial plants

Frequently Asked Questions (FAQ)

What does the model number 330101-00-16-05-02-05 represent?

It designates a proximity probe system with a total length of 16 ft (5 ft probe + 11 ft extension), with specific connector and thread type.

Can this probe be used in explosive atmospheres?

Certain versions with ATEX/IECEx certifications are suitable for hazardous zones.

What sensor should I pair with this probe?

It is compatible with Bently Nevada 3300 XL Proximitor Sensors for accurate system response.

Does this probe meet API 670 standards?

Yes, it complies fully with API 670 performance and reliability criteria.

What cable materials are used?

The extension cable uses a polyurethane jacket for superior abrasion and chemical resistance.

Is it suitable for high-temperature equipment?

Yes, it supports operating temperatures up to 177°C.

What vibration range does it measure?

The system measures dynamic motion within a 2 mm (80 mils) range with ±0.25% accuracy.

Can I cut or shorten the cable length on-site?

No. The total system length is factory-calibrated and must remain unchanged to ensure accuracy.

Does the probe require periodic calibration?

No field calibration is needed, but it is recommended to follow standard maintenance checks.

What maintenance does this product require?

Routine inspection for physical damage and secure connections is typically sufficient.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...