Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

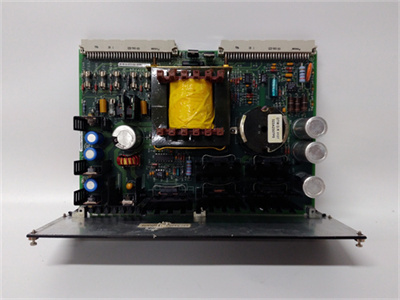

General Electric IS200PAICH1B Turbine Protection Board

Manufacturer:GE

Product Number:IS200PAICH1B

Product Type:Turbine Protection Board

Origin:USA

Dimensions:127 x 127 x 132 mm

Weight:0.4 kg

Views:26

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200PAICH1B is a high-performance Turbine Protection Board designed for use within the GE Mark VI and Mark VIe series of turbine control systems. Specifically engineered to manage analog signal acquisition and conditioning, this board plays a critical role in monitoring turbine operating parameters such as pressure, vibration, and temperature, feeding these inputs directly into the control system’s logic processors for real-time protection and control actions.

This board is a key component of GE’s integrated control and protection architecture, offering precision input handling for analog signals in demanding industrial environments. The IS200PAICH1B interfaces seamlessly with input terminal boards such as STAI or TBTH, filtering, scaling, and isolating analog signals before delivering them to the controller through the IONet communication bus.

It is typically used in steam, gas, and hydro turbine systems, ensuring timely fault detection and safe shutdown capabilities, contributing to asset reliability and operational safety.

Product Specifications

| Parameter | Description |

|---|---|

| Model | IS200PAICH1B |

| Part Number | IS200PAICH1B |

| Function | Analog Input Conditioning for Turbine Protection |

| Signal Input Type | 4–20 mA, 1–5 V, ±10 V analog inputs |

| Channels Supported | Up to 20 analog input channels |

| Filtering Type | Low-pass filtering for noise suppression |

| Signal Isolation | Galvanic isolation between input and control side |

| Power Supply | Supplied via backplane from control rack |

| Communication Interface | IONet (via associated VCMI module) |

| System Compatibility | GE Mark VI, Mark VIe |

| Redundancy Support | Yes, supports redundant architecture |

| Diagnostics | Continuous onboard health and signal validation |

| Hot Swappable | No |

| Mounting Style | Rack-mounted (via control system frame) |

| PCB Material | Multilayer FR4 with conformal coating |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions (W × H × D) | 127 x 127 x 132 mm |

| Weight | 0.4 kg |

| Certifications | CE, UL, CSA, RoHS compliant |

Product Applications

The IS200PAICH1B board is specifically engineered for turbine protection and monitoring in mission-critical applications. Key usage scenarios include:

-

Gas Turbine Control Systems – Monitoring combustion chamber temperatures, fuel pressures, and vibration to prevent mechanical or thermal failure.

-

Steam Turbine Monitoring – Conditioning analog signals from pressure transducers and flow meters for real-time load balancing.

-

Hydroelectric Plant Systems – Processing signals from water pressure sensors and flow rate instruments.

-

Boiler Feedwater Management – Interfacing with transmitters to ensure safe water levels and heat exchange rates.

-

Oil & Gas Process Safety – Integration into safety interlock systems in high-pressure environments.

-

Nuclear and Combined Cycle Plants – Supporting redundancy in safety-critical instrumentation loops.

Product Advantages

-

High Signal Accuracy: Built with precision signal conditioning to ensure reliable analog data conversion and transmission.

-

Noise Immunity: Advanced filtering and grounding techniques minimize signal distortion in electrically noisy environments.

-

Redundancy Ready: Designed to support dual-channel or redundant systems, maximizing system uptime and safety.

-

Robust Isolation: Galvanic isolation protects the controller and downstream electronics from transients and ground loops.

-

Plug-and-Play Integration: Seamless compatibility with GE Mark VI/VIe systems simplifies deployment and commissioning.

-

Long-Term Stability: Excellent thermal performance and low component drift ensure accuracy over extended operational cycles.

-

Modular Maintenance: Field-replaceable with clear labeling and diagnostic indicators to streamline troubleshooting.

-

Industrial Reliability: Engineered to withstand harsh plant conditions including vibration, temperature fluctuations, and humidity.

Frequently Asked Questions (FAQ)

-

What type of signals does the IS200PAICH1B board support?

It supports standard analog input signals including 4–20 mA, 1–5 V, and ±10 V.

-

Does this module include onboard signal filtering?

Yes, each channel is equipped with low-pass filters to reduce electrical noise.

-

Is the board galvanically isolated from the control system?

Yes, all input channels feature galvanic isolation for enhanced protection.

-

Can the IS200PAICH1B be used in redundant architectures?

Absolutely, it is designed for full compatibility with redundant system configurations.

-

How are the analog signals interfaced with this board?

Through terminal boards such as STAI or TBTH that are wired to field sensors.

-

Is the board hot-swappable during live operation?

No, it must be powered down before replacement or maintenance.

-

What diagnostics features are built into the board?

It performs real-time health checks on channel integrity and signal validity.

-

Which communication protocol does it use to relay data?

The board communicates via IONet, typically through a VCMI interface.

-

Can this module be used with third-party systems?

It is optimized for GE Mark VI/VIe systems and not typically used with third-party systems without significant adaptation.

-

What types of sensors can be connected to this board?

Any industrial-grade sensor that outputs standard analog signals such as pressure transducers, RTDs (via analog conversion), and flow meters.

General Electric IS200PAICH1B Turbine Protection Board

Manufacturer:GE

Product Number:IS200PAICH1B

Product Type:Turbine Protection Board

Origin:USA

Dimensions:127 x 127 x 132 mm

Weight:0.4 kg

Views:26

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200PAICH1B is a high-performance Turbine Protection Board designed for use within the GE Mark VI and Mark VIe series of turbine control systems. Specifically engineered to manage analog signal acquisition and conditioning, this board plays a critical role in monitoring turbine operating parameters such as pressure, vibration, and temperature, feeding these inputs directly into the control system’s logic processors for real-time protection and control actions.

This board is a key component of GE’s integrated control and protection architecture, offering precision input handling for analog signals in demanding industrial environments. The IS200PAICH1B interfaces seamlessly with input terminal boards such as STAI or TBTH, filtering, scaling, and isolating analog signals before delivering them to the controller through the IONet communication bus.

It is typically used in steam, gas, and hydro turbine systems, ensuring timely fault detection and safe shutdown capabilities, contributing to asset reliability and operational safety.

Product Specifications

| Parameter | Description |

|---|---|

| Model | IS200PAICH1B |

| Part Number | IS200PAICH1B |

| Function | Analog Input Conditioning for Turbine Protection |

| Signal Input Type | 4–20 mA, 1–5 V, ±10 V analog inputs |

| Channels Supported | Up to 20 analog input channels |

| Filtering Type | Low-pass filtering for noise suppression |

| Signal Isolation | Galvanic isolation between input and control side |

| Power Supply | Supplied via backplane from control rack |

| Communication Interface | IONet (via associated VCMI module) |

| System Compatibility | GE Mark VI, Mark VIe |

| Redundancy Support | Yes, supports redundant architecture |

| Diagnostics | Continuous onboard health and signal validation |

| Hot Swappable | No |

| Mounting Style | Rack-mounted (via control system frame) |

| PCB Material | Multilayer FR4 with conformal coating |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions (W × H × D) | 127 x 127 x 132 mm |

| Weight | 0.4 kg |

| Certifications | CE, UL, CSA, RoHS compliant |

Product Applications

The IS200PAICH1B board is specifically engineered for turbine protection and monitoring in mission-critical applications. Key usage scenarios include:

-

Gas Turbine Control Systems – Monitoring combustion chamber temperatures, fuel pressures, and vibration to prevent mechanical or thermal failure.

-

Steam Turbine Monitoring – Conditioning analog signals from pressure transducers and flow meters for real-time load balancing.

-

Hydroelectric Plant Systems – Processing signals from water pressure sensors and flow rate instruments.

-

Boiler Feedwater Management – Interfacing with transmitters to ensure safe water levels and heat exchange rates.

-

Oil & Gas Process Safety – Integration into safety interlock systems in high-pressure environments.

-

Nuclear and Combined Cycle Plants – Supporting redundancy in safety-critical instrumentation loops.

Product Advantages

-

High Signal Accuracy: Built with precision signal conditioning to ensure reliable analog data conversion and transmission.

-

Noise Immunity: Advanced filtering and grounding techniques minimize signal distortion in electrically noisy environments.

-

Redundancy Ready: Designed to support dual-channel or redundant systems, maximizing system uptime and safety.

-

Robust Isolation: Galvanic isolation protects the controller and downstream electronics from transients and ground loops.

-

Plug-and-Play Integration: Seamless compatibility with GE Mark VI/VIe systems simplifies deployment and commissioning.

-

Long-Term Stability: Excellent thermal performance and low component drift ensure accuracy over extended operational cycles.

-

Modular Maintenance: Field-replaceable with clear labeling and diagnostic indicators to streamline troubleshooting.

-

Industrial Reliability: Engineered to withstand harsh plant conditions including vibration, temperature fluctuations, and humidity.

Frequently Asked Questions (FAQ)

-

What type of signals does the IS200PAICH1B board support?

It supports standard analog input signals including 4–20 mA, 1–5 V, and ±10 V.

-

Does this module include onboard signal filtering?

Yes, each channel is equipped with low-pass filters to reduce electrical noise.

-

Is the board galvanically isolated from the control system?

Yes, all input channels feature galvanic isolation for enhanced protection.

-

Can the IS200PAICH1B be used in redundant architectures?

Absolutely, it is designed for full compatibility with redundant system configurations.

-

How are the analog signals interfaced with this board?

Through terminal boards such as STAI or TBTH that are wired to field sensors.

-

Is the board hot-swappable during live operation?

No, it must be powered down before replacement or maintenance.

-

What diagnostics features are built into the board?

It performs real-time health checks on channel integrity and signal validity.

-

Which communication protocol does it use to relay data?

The board communicates via IONet, typically through a VCMI interface.

-

Can this module be used with third-party systems?

It is optimized for GE Mark VI/VIe systems and not typically used with third-party systems without significant adaptation.

-

What types of sensors can be connected to this board?

Any industrial-grade sensor that outputs standard analog signals such as pressure transducers, RTDs (via analog conversion), and flow meters.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...