Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

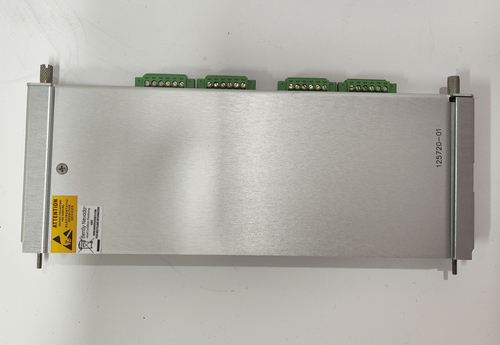

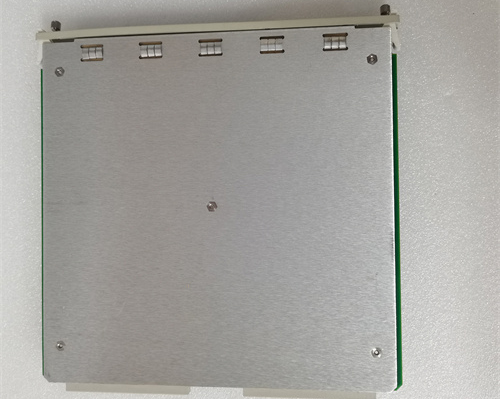

Bently Nevada 330104-01-08-50-01-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-01-08-50-01-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:5 m

Weight:1.615 kg

Views:109

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-01-08-50-01-05 is a part of the globally respected 3300 XL 8 mm Proximity Transducer System, known for its precision, ruggedness, and long-term reliability in industrial vibration monitoring and machinery protection. This particular probe is designed with an 5-meter system length, suitable for applications where the sensor and driver need to be spaced moderately apart due to layout constraints, temperature zones, or hazardous classifications.

This model is equipped with a 50-series ClickLoc connector, offering improved cable retention and resistance to mechanical loosening due to high vibration. Engineered to deliver accurate non-contact displacement measurements of rotating shafts, this proximity probe is commonly used in turbines, compressors, and high-speed industrial equipment where shaft vibration and position monitoring is critical for operational safety and efficiency.

Product Specifications

| Specification | Detail |

|---|---|

| Model Number | 330104-01-08-50-01-05 |

| Product Series | 3300 XL 8 mm |

| Measurement Range | -2 mm to +2 mm (±80 mils) |

| Linear Range | ±1 mm (±40 mils) |

| Sensitivity | 7.87 mV/µm (200 mV/mil) |

| Total Length | 5 meters |

| Connector Type | 50-series ClickLoc, 2-pin axial |

| Thread Size | 3/8-24 UNF |

| Probe Tip Diameter | 8 mm (0.31 in) |

| Probe Body Diameter | 9.52 mm (0.375 in) |

| Overall Probe Length | 71.1 mm (2.80 in) |

| Case Material | AISI 303 Stainless Steel |

| Operating Temperature | -35°C to +120°C (-31°F to +248°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +350°F) |

| Maximum Pressure Rating | 10.3 bar (150 psi) |

| Vibration Tolerance | 20 g, 10–2000 Hz |

| Shock Resistance | 5000 g, 1 ms half-sine |

| Ingress Protection | IP67 (dust-tight and water immersion rated) |

| Weight | 1.615 kg |

| Compliance | CE, RoHS compliant; optional ATEX/IECEx with approved system integration |

Applications

The 330104-01-08-50-01-05 proximity probe is designed for monitoring both dynamic vibration and static shaft position in a wide variety of rotating and reciprocating machines. Its most common applications include:

-

Steam and Gas Turbines – For detecting shaft eccentricity, vibration amplitudes, and rotor movement.

-

Axial Compressors – Monitoring vibration in high-speed rotary machinery.

-

Pumps and Fans – To monitor misalignment, cavitation, or shaft instability.

-

Motors and Generators – Assessing shaft displacement and ensuring proper operation.

-

Gearboxes and Speed Reducers – To detect abnormal shaft behavior or gear engagement anomalies.

-

Petrochemical and Refining Equipment – Particularly useful in ATEX-classified environments with potential exposure to gas or vapor.

Thanks to its robust build and sealing, it is also suited for offshore platforms, chemical processing plants, and remote compressor stations where environmental challenges are common.

Key Product Advantages

-

Secure Connection System: The 50-series ClickLoc connector provides enhanced connection security, preventing accidental disconnection under high-vibration environments.

-

Consistent Performance: Maintains measurement accuracy even in environments with temperature fluctuations or electromagnetic interference.

-

IP67 Rated Design: Dust-tight and protected from temporary immersion in liquids—ideal for harsh and dirty environments.

-

Durable Construction: Stainless steel housing ensures long service life even when exposed to oil, gas, and mechanical stress.

-

No Field Calibration Required: When used with compatible extension cables and drivers, factory-calibrated probe systems require no adjustment during installation.

-

Wide System Compatibility: Fully compatible with Bently Nevada 3300 XL drivers and monitors including rack-based and distributed systems.

-

Moderate-Length System Flexibility: The 5-meter length makes it ideal for mid-sized machine installations without excessive cabling.

Frequently Asked Questions (FAQ)

-

What type of driver or Proximitor should I use with this probe?

Use the 3300 XL Proximitor Sensor (P/N 3300-15-XX) that corresponds to the 8 mm probe system for best accuracy and linearity.

-

Is this probe rated for hazardous environments?

Yes, when installed as part of an ATEX- or IECEx-certified system, it is safe for use in explosive or flammable environments.

-

Can the probe be installed near hot surfaces?

The probe is rated for up to 120°C. Ensure that mounting points do not exceed this range during operation.

-

Does this model require any software configuration?

No, it’s a passive analog device. Calibration is mechanical, and it integrates seamlessly with vibration monitoring systems.

-

What kind of shaft materials does it work best with?

It is factory calibrated for AISI 4140 steel, but can be recalibrated for other materials using correction factors.

-

Can it detect both vibration and shaft position?

Yes, this proximity probe is designed to detect both dynamic (AC) vibration and static (DC) position.

-

What’s the function of the ClickLoc connector?

It provides a secure, vibration-resistant connection that prevents accidental loosening.

-

Is the probe shielded against electrical noise?

Yes, the cable and connector are fully shielded to prevent EMI/RFI interference.

-

Can I extend the cable length beyond 5 meters?

No, system length must match the specified 5 meters (probe + extension cable) for calibration accuracy.

-

How do I clean or maintain the probe?

Clean using a soft lint-free cloth and mild solvent. Avoid abrasive cleaning materials or strong chemicals.

Bently Nevada 330104-01-08-50-01-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-01-08-50-01-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:5 m

Weight:1.615 kg

Views:109

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-01-08-50-01-05 is a part of the globally respected 3300 XL 8 mm Proximity Transducer System, known for its precision, ruggedness, and long-term reliability in industrial vibration monitoring and machinery protection. This particular probe is designed with an 5-meter system length, suitable for applications where the sensor and driver need to be spaced moderately apart due to layout constraints, temperature zones, or hazardous classifications.

This model is equipped with a 50-series ClickLoc connector, offering improved cable retention and resistance to mechanical loosening due to high vibration. Engineered to deliver accurate non-contact displacement measurements of rotating shafts, this proximity probe is commonly used in turbines, compressors, and high-speed industrial equipment where shaft vibration and position monitoring is critical for operational safety and efficiency.

Product Specifications

| Specification | Detail |

|---|---|

| Model Number | 330104-01-08-50-01-05 |

| Product Series | 3300 XL 8 mm |

| Measurement Range | -2 mm to +2 mm (±80 mils) |

| Linear Range | ±1 mm (±40 mils) |

| Sensitivity | 7.87 mV/µm (200 mV/mil) |

| Total Length | 5 meters |

| Connector Type | 50-series ClickLoc, 2-pin axial |

| Thread Size | 3/8-24 UNF |

| Probe Tip Diameter | 8 mm (0.31 in) |

| Probe Body Diameter | 9.52 mm (0.375 in) |

| Overall Probe Length | 71.1 mm (2.80 in) |

| Case Material | AISI 303 Stainless Steel |

| Operating Temperature | -35°C to +120°C (-31°F to +248°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +350°F) |

| Maximum Pressure Rating | 10.3 bar (150 psi) |

| Vibration Tolerance | 20 g, 10–2000 Hz |

| Shock Resistance | 5000 g, 1 ms half-sine |

| Ingress Protection | IP67 (dust-tight and water immersion rated) |

| Weight | 1.615 kg |

| Compliance | CE, RoHS compliant; optional ATEX/IECEx with approved system integration |

Applications

The 330104-01-08-50-01-05 proximity probe is designed for monitoring both dynamic vibration and static shaft position in a wide variety of rotating and reciprocating machines. Its most common applications include:

-

Steam and Gas Turbines – For detecting shaft eccentricity, vibration amplitudes, and rotor movement.

-

Axial Compressors – Monitoring vibration in high-speed rotary machinery.

-

Pumps and Fans – To monitor misalignment, cavitation, or shaft instability.

-

Motors and Generators – Assessing shaft displacement and ensuring proper operation.

-

Gearboxes and Speed Reducers – To detect abnormal shaft behavior or gear engagement anomalies.

-

Petrochemical and Refining Equipment – Particularly useful in ATEX-classified environments with potential exposure to gas or vapor.

Thanks to its robust build and sealing, it is also suited for offshore platforms, chemical processing plants, and remote compressor stations where environmental challenges are common.

Key Product Advantages

-

Secure Connection System: The 50-series ClickLoc connector provides enhanced connection security, preventing accidental disconnection under high-vibration environments.

-

Consistent Performance: Maintains measurement accuracy even in environments with temperature fluctuations or electromagnetic interference.

-

IP67 Rated Design: Dust-tight and protected from temporary immersion in liquids—ideal for harsh and dirty environments.

-

Durable Construction: Stainless steel housing ensures long service life even when exposed to oil, gas, and mechanical stress.

-

No Field Calibration Required: When used with compatible extension cables and drivers, factory-calibrated probe systems require no adjustment during installation.

-

Wide System Compatibility: Fully compatible with Bently Nevada 3300 XL drivers and monitors including rack-based and distributed systems.

-

Moderate-Length System Flexibility: The 5-meter length makes it ideal for mid-sized machine installations without excessive cabling.

Frequently Asked Questions (FAQ)

-

What type of driver or Proximitor should I use with this probe?

Use the 3300 XL Proximitor Sensor (P/N 3300-15-XX) that corresponds to the 8 mm probe system for best accuracy and linearity.

-

Is this probe rated for hazardous environments?

Yes, when installed as part of an ATEX- or IECEx-certified system, it is safe for use in explosive or flammable environments.

-

Can the probe be installed near hot surfaces?

The probe is rated for up to 120°C. Ensure that mounting points do not exceed this range during operation.

-

Does this model require any software configuration?

No, it’s a passive analog device. Calibration is mechanical, and it integrates seamlessly with vibration monitoring systems.

-

What kind of shaft materials does it work best with?

It is factory calibrated for AISI 4140 steel, but can be recalibrated for other materials using correction factors.

-

Can it detect both vibration and shaft position?

Yes, this proximity probe is designed to detect both dynamic (AC) vibration and static (DC) position.

-

What’s the function of the ClickLoc connector?

It provides a secure, vibration-resistant connection that prevents accidental loosening.

-

Is the probe shielded against electrical noise?

Yes, the cable and connector are fully shielded to prevent EMI/RFI interference.

-

Can I extend the cable length beyond 5 meters?

No, system length must match the specified 5 meters (probe + extension cable) for calibration accuracy.

-

How do I clean or maintain the probe?

Clean using a soft lint-free cloth and mild solvent. Avoid abrasive cleaning materials or strong chemicals.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...