Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

Bently Nevada 330901-00-21-05-12-05 3300 NSv Proximity Probe

Manufacturer:Bently Nevada

Product Number:330901-00-21-05-12-05

Product Type:3300 NSv Proximity Probe

Origin:USA

Dimensions:0.5 m

Weight :3 kg

Views:18

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

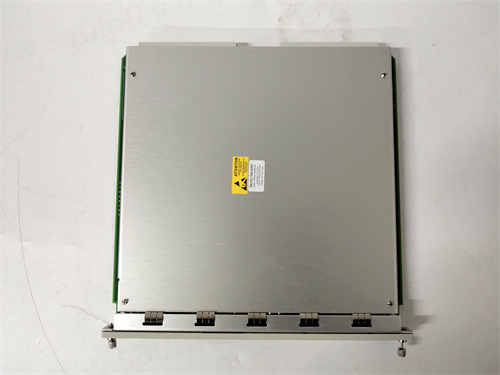

The Bently Nevada 330901-00-21-05-12-05 3300 NSv Proximity Probe is a precision monitoring device designed for machinery vibration measurement and shaft position detection in environments where space is restricted. Part of the 3300 NSv (Narrow Side-view) series, it provides reliable proximity sensing performance with high stability and repeatability.

This probe is widely used in industrial turbomachinery, compressors, pumps, and gearboxes to detect changes in shaft dynamics, offering critical insights for condition monitoring systems. With its rugged design and compatibility with Bently Nevada monitoring systems, the 3300 NSv probe ensures accurate data acquisition even in demanding operational conditions.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330901-00-21-05-12-05 |

| Series | 3300 NSv Proximity Probe |

| Total Length | 0.5 m |

| Probe Tip Diameter | 8 mm |

| Weight | 3 kg |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Operating Temperature | -35 °C to +177 °C |

| Power Supply (via driver) | -24 VDC regulated |

| Mounting Thread | M10 × 1 or compatible |

Product Applications

Steam and gas turbines – shaft vibration and axial displacement monitoring.

Compressors – detecting rotor instabilities and mechanical faults.

Gearboxes and pumps – continuous monitoring of rotating elements.

Electric motors – identifying unbalance, misalignment, or bearing wear.

Narrow installation spaces – optimized for use where probe access is limited.

Product Advantages

Compact design – suitable for confined installation areas without sacrificing measurement accuracy.

High accuracy – ensures reliable readings for vibration and displacement detection.

Wide compatibility – fully integrates with Bently Nevada monitoring systems.

Rugged durability – stainless steel construction for harsh industrial environments.

Extended temperature range – performs reliably under extreme thermal conditions.

Stable performance – minimizes signal drift and ensures consistent measurements.

FAQ

Q1: How does the 330901-00-21-05-12-05 probe interface with the monitoring system?

A1: It connects through an extension cable to the 3300 NSv driver, which conditions and transmits the signal to the monitoring system.

Q2: What is the primary output of this probe?

A2: The probe provides a voltage proportional to the distance between the probe tip and the shaft surface.

Q3: Is the probe suitable for high-speed rotating machinery?

A3: Yes, it is optimized for turbomachinery and other high-speed applications requiring precise vibration monitoring.

Q4: Can the probe detect both vibration and position?

A4: Yes, it measures dynamic vibration as well as static shaft position (axial displacement).

Q5: What type of target material does it require for accurate operation?

A5: The probe is designed for conductive targets, typically steel shaft surfaces.

Q6: How does the probe handle electrical noise?

A6: Shielded cabling and proper grounding minimize interference, ensuring signal integrity.

Q7: What happens if the probe-to-target gap exceeds its linear range?

A7: The output becomes nonlinear, reducing measurement accuracy and requiring repositioning.

Q8: Can this probe be used interchangeably with standard 3300 XL probes?

A8: No, the 3300 NSv series is specifically designed for narrow-space applications and requires its matching drivers and cables.

Q9: Does the probe require calibration in the field?

A9: No, the probe is factory-calibrated but should be installed at the recommended gap to ensure accuracy.

Q10: How does the probe behave under extreme temperature variations?

A10: It maintains performance within its specified operating temperature range of -35 °C to +177 °C.

Bently Nevada 330901-00-21-05-12-05 3300 NSv Proximity Probe

Manufacturer:Bently Nevada

Product Number:330901-00-21-05-12-05

Product Type:3300 NSv Proximity Probe

Origin:USA

Dimensions:0.5 m

Weight :3 kg

Views:18

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330901-00-21-05-12-05 3300 NSv Proximity Probe is a precision monitoring device designed for machinery vibration measurement and shaft position detection in environments where space is restricted. Part of the 3300 NSv (Narrow Side-view) series, it provides reliable proximity sensing performance with high stability and repeatability.

This probe is widely used in industrial turbomachinery, compressors, pumps, and gearboxes to detect changes in shaft dynamics, offering critical insights for condition monitoring systems. With its rugged design and compatibility with Bently Nevada monitoring systems, the 3300 NSv probe ensures accurate data acquisition even in demanding operational conditions.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330901-00-21-05-12-05 |

| Series | 3300 NSv Proximity Probe |

| Total Length | 0.5 m |

| Probe Tip Diameter | 8 mm |

| Weight | 3 kg |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Operating Temperature | -35 °C to +177 °C |

| Power Supply (via driver) | -24 VDC regulated |

| Mounting Thread | M10 × 1 or compatible |

Product Applications

Steam and gas turbines – shaft vibration and axial displacement monitoring.

Compressors – detecting rotor instabilities and mechanical faults.

Gearboxes and pumps – continuous monitoring of rotating elements.

Electric motors – identifying unbalance, misalignment, or bearing wear.

Narrow installation spaces – optimized for use where probe access is limited.

Product Advantages

Compact design – suitable for confined installation areas without sacrificing measurement accuracy.

High accuracy – ensures reliable readings for vibration and displacement detection.

Wide compatibility – fully integrates with Bently Nevada monitoring systems.

Rugged durability – stainless steel construction for harsh industrial environments.

Extended temperature range – performs reliably under extreme thermal conditions.

Stable performance – minimizes signal drift and ensures consistent measurements.

FAQ

Q1: How does the 330901-00-21-05-12-05 probe interface with the monitoring system?

A1: It connects through an extension cable to the 3300 NSv driver, which conditions and transmits the signal to the monitoring system.

Q2: What is the primary output of this probe?

A2: The probe provides a voltage proportional to the distance between the probe tip and the shaft surface.

Q3: Is the probe suitable for high-speed rotating machinery?

A3: Yes, it is optimized for turbomachinery and other high-speed applications requiring precise vibration monitoring.

Q4: Can the probe detect both vibration and position?

A4: Yes, it measures dynamic vibration as well as static shaft position (axial displacement).

Q5: What type of target material does it require for accurate operation?

A5: The probe is designed for conductive targets, typically steel shaft surfaces.

Q6: How does the probe handle electrical noise?

A6: Shielded cabling and proper grounding minimize interference, ensuring signal integrity.

Q7: What happens if the probe-to-target gap exceeds its linear range?

A7: The output becomes nonlinear, reducing measurement accuracy and requiring repositioning.

Q8: Can this probe be used interchangeably with standard 3300 XL probes?

A8: No, the 3300 NSv series is specifically designed for narrow-space applications and requires its matching drivers and cables.

Q9: Does the probe require calibration in the field?

A9: No, the probe is factory-calibrated but should be installed at the recommended gap to ensure accuracy.

Q10: How does the probe behave under extreme temperature variations?

A10: It maintains performance within its specified operating temperature range of -35 °C to +177 °C.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...