Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

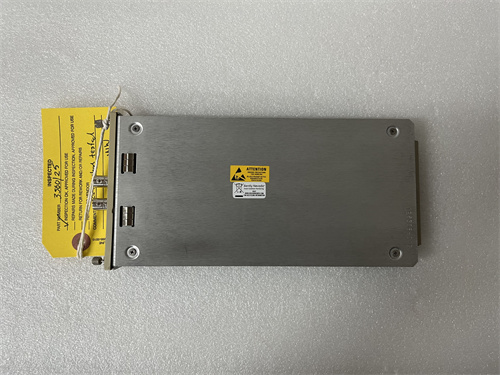

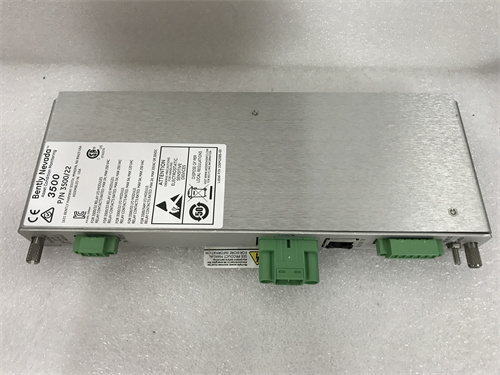

Bently Nevada 3500/40M-01-00 140734-01 3500/40M Proximitor Monitor

Manufacturer:Bently Nevada

Product Number:3500/40M-01-00 140734-01

Product Type:3500/40M Proximitor Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91kg

Views:49

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/40M-01-00 140734-01 Proximitor Monitor is a high-performance monitoring module designed for precise measurement of shaft vibration, position, and keyphasor signals in rotating machinery. As part of the industry-trusted Bently Nevada 3500 Machinery Protection System, the 3500/40M Proximitor Monitor delivers accurate, continuous condition monitoring essential for predictive maintenance and machinery protection.

This module integrates seamlessly with proximity probes and Proximitor sensors, providing real-time data on shaft movement to prevent catastrophic failures in critical assets such as turbines, compressors, and pumps.

Key Features

-

Continuous monitoring of shaft radial vibration, axial position, and phase reference (keyphasor) signals

-

Compatible with Bently Nevada 3300 XL and 7200 series proximity probes and sensors

-

Supports multiple transducer configurations for versatile applications

-

High-resolution vibration and position measurement for early fault detection

-

Designed for use in the Bently Nevada 3500 machinery protection platform

-

LED indicators for channel health, module status, and system diagnostics

-

Field-configurable for customized alarm setpoints and monitoring parameters

-

Industrial-grade construction for operation in harsh environments

-

Supports API 670 compliance for critical rotating machinery

Technical Specifications

| Specification | Details |

|---|---|

| Product Name | 3500/40M Proximitor Monitor |

| Model Number | 3500/40M-01-00 |

| Part Number | 140734-01 |

| Number of Channels | 2 independent channels per module |

| Measurement Types | Shaft radial vibration, axial position, keyphasor signals |

| Compatible Probes | Bently Nevada 3300 XL, 7200 Series Proximity Probes |

| Measurement Range (Radial Vibration) | 0 to 200 μm (8 mils) peak-to-peak |

| Measurement Range (Axial Position) | ±2 mm (±80 mils) |

| Frequency Response | 0 to 20 kHz typical |

| Alarm Outputs | Configurable alert and danger alarms via relay modules |

| Signal Conditioning | Integrated signal processing and filtering |

| Communication Interface | Connects to 3500 rack via backplane |

| Diagnostics | LED indicators for OK, ALERT, DANGER, and Bypass status |

| Operating Voltage (Control) | Supplied via 3500 System rack |

| Operating Temperature Range | -30°C to +65°C |

| Storage Temperature Range | -40°C to +85°C |

| Certifications | CE, CSA, ATEX, IECEx (region-specific) |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Industry Applications

The 3500/40M Proximitor Monitor is utilized across industries where rotating equipment health monitoring is vital:

Oil & Gas: Compressor, turbine, and pump shaft vibration and position monitoring

Power Generation: Steam and gas turbine condition monitoring

Petrochemical: Machinery protection in chemical processing plants

Metals & Mining: Vibration monitoring for mills, crushers, and conveyors

Marine & Offshore: Shaft position and vibration monitoring for propulsion systems

Industrial Manufacturing: Condition monitoring for critical rotating assets

Product Advantages

High-Precision Monitoring: Provides accurate shaft vibration, position, and keyphasor measurements

Predictive Maintenance Support: Enables early detection of mechanical faults, reducing unplanned downtime

Seamless System Integration: Fully compatible with Bently Nevada 3500 System architecture

Multiple Measurement Functions: Supports radial vibration, axial position, and phase reference monitoring in one module

Robust Industrial Design: Engineered for continuous operation in harsh industrial environments

API 670 Compliance: Meets global standards for machinery protection in critical applications

Configurable Alarms: User-defined alert and danger setpoints for tailored protection schemes

Simplified Diagnostics: LED indicators streamline troubleshooting and maintenance procedures

Frequently Asked Questions (FAQ)

1. What is the primary function of the 3500/40M Proximitor Monitor?

It continuously monitors shaft radial vibration, axial position, and keyphasor signals in rotating machinery for condition monitoring and protection.

2. Which proximity probes are compatible with this module?

The module is compatible with Bently Nevada 3300 XL and 7200 series proximity probes and Proximitor sensors.

3. How many channels does the 3500/40M provide?

Each module provides 2 independent monitoring channels.

4. Can the module generate alarms?

Yes, it supports configurable alert and danger alarms, typically interfaced via relay modules in the 3500 system.

5. Does the 3500/40M support keyphasor measurements?

Yes, it provides phase reference (keyphasor) signals essential for machinery diagnostics and vibration analysis.

6. Is the module compliant with industry standards?

Yes, it is designed to support API 670 compliance for machinery protection.

7. What operating environments is the module suitable for?

It operates reliably in industrial environments with temperatures ranging from -30°C to +65°C.

8. Are LED indicators included for diagnostics?

Yes, LED indicators provide status for OK, ALERT, DANGER, and Bypass conditions.

9. How is the module powered?

It receives power through the 3500 System rack backplane.

10. In which industries is this monitor commonly used?

It is widely used in oil & gas, power generation, petrochemical, marine, mining, and industrial manufacturing sectors.

Bently Nevada 3500/40M-01-00 140734-01 3500/40M Proximitor Monitor

Manufacturer:Bently Nevada

Product Number:3500/40M-01-00 140734-01

Product Type:3500/40M Proximitor Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91kg

Views:49

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/40M-01-00 140734-01 Proximitor Monitor is a high-performance monitoring module designed for precise measurement of shaft vibration, position, and keyphasor signals in rotating machinery. As part of the industry-trusted Bently Nevada 3500 Machinery Protection System, the 3500/40M Proximitor Monitor delivers accurate, continuous condition monitoring essential for predictive maintenance and machinery protection.

This module integrates seamlessly with proximity probes and Proximitor sensors, providing real-time data on shaft movement to prevent catastrophic failures in critical assets such as turbines, compressors, and pumps.

Key Features

-

Continuous monitoring of shaft radial vibration, axial position, and phase reference (keyphasor) signals

-

Compatible with Bently Nevada 3300 XL and 7200 series proximity probes and sensors

-

Supports multiple transducer configurations for versatile applications

-

High-resolution vibration and position measurement for early fault detection

-

Designed for use in the Bently Nevada 3500 machinery protection platform

-

LED indicators for channel health, module status, and system diagnostics

-

Field-configurable for customized alarm setpoints and monitoring parameters

-

Industrial-grade construction for operation in harsh environments

-

Supports API 670 compliance for critical rotating machinery

Technical Specifications

| Specification | Details |

|---|---|

| Product Name | 3500/40M Proximitor Monitor |

| Model Number | 3500/40M-01-00 |

| Part Number | 140734-01 |

| Number of Channels | 2 independent channels per module |

| Measurement Types | Shaft radial vibration, axial position, keyphasor signals |

| Compatible Probes | Bently Nevada 3300 XL, 7200 Series Proximity Probes |

| Measurement Range (Radial Vibration) | 0 to 200 μm (8 mils) peak-to-peak |

| Measurement Range (Axial Position) | ±2 mm (±80 mils) |

| Frequency Response | 0 to 20 kHz typical |

| Alarm Outputs | Configurable alert and danger alarms via relay modules |

| Signal Conditioning | Integrated signal processing and filtering |

| Communication Interface | Connects to 3500 rack via backplane |

| Diagnostics | LED indicators for OK, ALERT, DANGER, and Bypass status |

| Operating Voltage (Control) | Supplied via 3500 System rack |

| Operating Temperature Range | -30°C to +65°C |

| Storage Temperature Range | -40°C to +85°C |

| Certifications | CE, CSA, ATEX, IECEx (region-specific) |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Industry Applications

The 3500/40M Proximitor Monitor is utilized across industries where rotating equipment health monitoring is vital:

Oil & Gas: Compressor, turbine, and pump shaft vibration and position monitoring

Power Generation: Steam and gas turbine condition monitoring

Petrochemical: Machinery protection in chemical processing plants

Metals & Mining: Vibration monitoring for mills, crushers, and conveyors

Marine & Offshore: Shaft position and vibration monitoring for propulsion systems

Industrial Manufacturing: Condition monitoring for critical rotating assets

Product Advantages

High-Precision Monitoring: Provides accurate shaft vibration, position, and keyphasor measurements

Predictive Maintenance Support: Enables early detection of mechanical faults, reducing unplanned downtime

Seamless System Integration: Fully compatible with Bently Nevada 3500 System architecture

Multiple Measurement Functions: Supports radial vibration, axial position, and phase reference monitoring in one module

Robust Industrial Design: Engineered for continuous operation in harsh industrial environments

API 670 Compliance: Meets global standards for machinery protection in critical applications

Configurable Alarms: User-defined alert and danger setpoints for tailored protection schemes

Simplified Diagnostics: LED indicators streamline troubleshooting and maintenance procedures

Frequently Asked Questions (FAQ)

1. What is the primary function of the 3500/40M Proximitor Monitor?

It continuously monitors shaft radial vibration, axial position, and keyphasor signals in rotating machinery for condition monitoring and protection.

2. Which proximity probes are compatible with this module?

The module is compatible with Bently Nevada 3300 XL and 7200 series proximity probes and Proximitor sensors.

3. How many channels does the 3500/40M provide?

Each module provides 2 independent monitoring channels.

4. Can the module generate alarms?

Yes, it supports configurable alert and danger alarms, typically interfaced via relay modules in the 3500 system.

5. Does the 3500/40M support keyphasor measurements?

Yes, it provides phase reference (keyphasor) signals essential for machinery diagnostics and vibration analysis.

6. Is the module compliant with industry standards?

Yes, it is designed to support API 670 compliance for machinery protection.

7. What operating environments is the module suitable for?

It operates reliably in industrial environments with temperatures ranging from -30°C to +65°C.

8. Are LED indicators included for diagnostics?

Yes, LED indicators provide status for OK, ALERT, DANGER, and Bypass conditions.

9. How is the module powered?

It receives power through the 3500 System rack backplane.

10. In which industries is this monitor commonly used?

It is widely used in oil & gas, power generation, petrochemical, marine, mining, and industrial manufacturing sectors.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...