Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

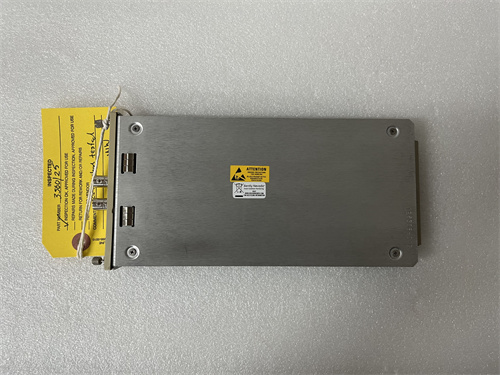

Bently Nevada 21504-00-08-05-02 7200 8 mm Standard Mount Probe

Manufacturer:Bently Nevada

Product Number:21504-00-08-05-02

Product Type:7200 8 mm Standard Mount Probe

Origin:USA

Total Length:0.5 m

Weight:0.23 kg

Views:51

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

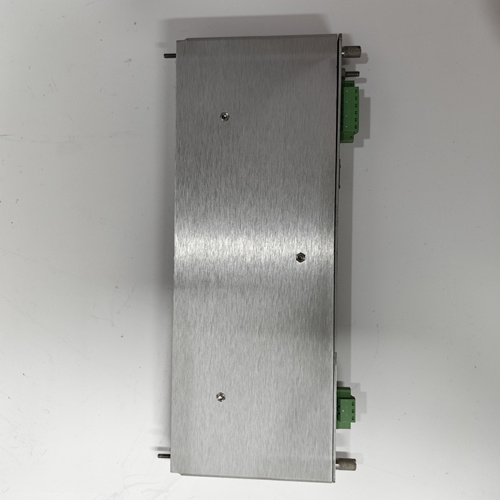

The Bently Nevada 21504-00-08-05-02 is a standard mount proximity probe designed for use in critical machinery condition monitoring systems. As a part of the 7200 Series 8 mm proximity transducer system, this probe is engineered to deliver accurate, reliable measurements of shaft position and vibration in rotating machinery. It is fully compatible with the Bently Nevada monitoring systems and is widely used in power generation, petrochemical, and industrial environments.

This proximity probe is manufactured to stringent standards, ensuring precision alignment, ease of installation, and long-term stability. The probe is encapsulated in a robust stainless steel housing that offers excellent resistance to corrosion and mechanical wear, making it ideal for harsh environments.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 21504-00-08-05-02 |

| Series | 7200 8 mm Proximity Transducer System |

| Sensing Range | 0 to 2 mm (80 mils) |

| Linear Range | 0.25 mm to 2.00 mm (10 mils to 80 mils) |

| Probe Tip Diameter | 8 mm |

| Thread Size | 3/8-24 UNF-2A |

| Case Material | AISI 303 Stainless Steel |

| Cable Length | 0.5 meter |

| Connector Type | Miniature coaxial connector (male) |

| Operating Temperature Range | -35°C to +120°C (-31°F to +248°F) |

| Pressure Rating | Up to 500 psi (34 bar) |

| Mounting Style | Threaded with lock nut |

| Weight | 0.23 kg |

| Insulation Resistance | >100 MΩ at 500 VDC |

| Compatible Extension Cable | Bently Nevada 330130 Series |

| Compliance | CE, RoHS compliant |

Product Applications

-

Ideal for measuring shaft displacement, vibration, and axial thrust in turbines, compressors, motors, pumps, and gearboxes.

Power Generation Equipment

Used in gas and steam turbines for real-time monitoring and protection.

Petrochemical and Refining Plants

Employed in hazardous and high-temperature environments for vibration monitoring.

Pulp and Paper Industry

Applied in process-critical equipment to avoid unplanned downtime.

General Industrial Machinery

Suitable for OEM and retrofit installations requiring robust vibration measurement.

Product Advantages

High Accuracy and Sensitivity

Delivers precise vibration and displacement measurements over a wide range.

Proven Field Performance

Trusted for over decades in thousands of critical installations worldwide.

Robust and Durable Construction

Stainless steel housing ensures high resistance to environmental and mechanical stresses.

Wide Compatibility

Fully integrates with Bently Nevada 7200 and 3300 monitoring systems.

Easy Installation and Maintenance

Threaded body and standard cable connector facilitate fast field servicing.

Low Signal Noise

Provides a clean and reliable signal with minimal interference.

Frequently Asked Questions (FAQ)

What is the main function of the 21504-00-08-05-02 proximity probe?

It measures the relative distance between the probe tip and a conductive target such as a rotating shaft, enabling vibration and displacement monitoring.

Is the probe compatible with the 3300 series monitoring systems?

Yes, it can be used with certain 3300 series systems when properly configured.

Can this probe operate in hazardous environments?

Yes, the stainless steel construction and design allow it to be used in hazardous and high-temperature areas.

What is the maximum operating temperature?

The probe operates reliably in temperatures up to +120°C (248°F).

What is the difference between the 8 mm and 5 mm probe series?

The 8 mm probe offers a wider linear range and is typically used for applications requiring higher accuracy and robustness.

Is field calibration required after installation?

Generally, factory calibration suffices, but field verification is recommended during commissioning.

What kind of extension cables are compatible with this probe?

Bently Nevada 330130 series extension cables are compatible.

How long is the standard cable with the 21504-00-08-05-02 model?

This model comes with a standard 0.5 meter cable.

What is the expected service life of the probe?

Under normal operating conditions, it can last several years without significant performance degradation.

Is the probe suitable for OEM machinery design?

Yes, its threaded design and compact form factor make it ideal for integration into OEM systems.

Bently Nevada 21504-00-08-05-02 7200 8 mm Standard Mount Probe

Manufacturer:Bently Nevada

Product Number:21504-00-08-05-02

Product Type:7200 8 mm Standard Mount Probe

Origin:USA

Total Length:0.5 m

Weight:0.23 kg

Views:51

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 21504-00-08-05-02 is a standard mount proximity probe designed for use in critical machinery condition monitoring systems. As a part of the 7200 Series 8 mm proximity transducer system, this probe is engineered to deliver accurate, reliable measurements of shaft position and vibration in rotating machinery. It is fully compatible with the Bently Nevada monitoring systems and is widely used in power generation, petrochemical, and industrial environments.

This proximity probe is manufactured to stringent standards, ensuring precision alignment, ease of installation, and long-term stability. The probe is encapsulated in a robust stainless steel housing that offers excellent resistance to corrosion and mechanical wear, making it ideal for harsh environments.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 21504-00-08-05-02 |

| Series | 7200 8 mm Proximity Transducer System |

| Sensing Range | 0 to 2 mm (80 mils) |

| Linear Range | 0.25 mm to 2.00 mm (10 mils to 80 mils) |

| Probe Tip Diameter | 8 mm |

| Thread Size | 3/8-24 UNF-2A |

| Case Material | AISI 303 Stainless Steel |

| Cable Length | 0.5 meter |

| Connector Type | Miniature coaxial connector (male) |

| Operating Temperature Range | -35°C to +120°C (-31°F to +248°F) |

| Pressure Rating | Up to 500 psi (34 bar) |

| Mounting Style | Threaded with lock nut |

| Weight | 0.23 kg |

| Insulation Resistance | >100 MΩ at 500 VDC |

| Compatible Extension Cable | Bently Nevada 330130 Series |

| Compliance | CE, RoHS compliant |

Product Applications

-

Ideal for measuring shaft displacement, vibration, and axial thrust in turbines, compressors, motors, pumps, and gearboxes.

Power Generation Equipment

Used in gas and steam turbines for real-time monitoring and protection.

Petrochemical and Refining Plants

Employed in hazardous and high-temperature environments for vibration monitoring.

Pulp and Paper Industry

Applied in process-critical equipment to avoid unplanned downtime.

General Industrial Machinery

Suitable for OEM and retrofit installations requiring robust vibration measurement.

Product Advantages

High Accuracy and Sensitivity

Delivers precise vibration and displacement measurements over a wide range.

Proven Field Performance

Trusted for over decades in thousands of critical installations worldwide.

Robust and Durable Construction

Stainless steel housing ensures high resistance to environmental and mechanical stresses.

Wide Compatibility

Fully integrates with Bently Nevada 7200 and 3300 monitoring systems.

Easy Installation and Maintenance

Threaded body and standard cable connector facilitate fast field servicing.

Low Signal Noise

Provides a clean and reliable signal with minimal interference.

Frequently Asked Questions (FAQ)

What is the main function of the 21504-00-08-05-02 proximity probe?

It measures the relative distance between the probe tip and a conductive target such as a rotating shaft, enabling vibration and displacement monitoring.

Is the probe compatible with the 3300 series monitoring systems?

Yes, it can be used with certain 3300 series systems when properly configured.

Can this probe operate in hazardous environments?

Yes, the stainless steel construction and design allow it to be used in hazardous and high-temperature areas.

What is the maximum operating temperature?

The probe operates reliably in temperatures up to +120°C (248°F).

What is the difference between the 8 mm and 5 mm probe series?

The 8 mm probe offers a wider linear range and is typically used for applications requiring higher accuracy and robustness.

Is field calibration required after installation?

Generally, factory calibration suffices, but field verification is recommended during commissioning.

What kind of extension cables are compatible with this probe?

Bently Nevada 330130 series extension cables are compatible.

How long is the standard cable with the 21504-00-08-05-02 model?

This model comes with a standard 0.5 meter cable.

What is the expected service life of the probe?

Under normal operating conditions, it can last several years without significant performance degradation.

Is the probe suitable for OEM machinery design?

Yes, its threaded design and compact form factor make it ideal for integration into OEM systems.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...