Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

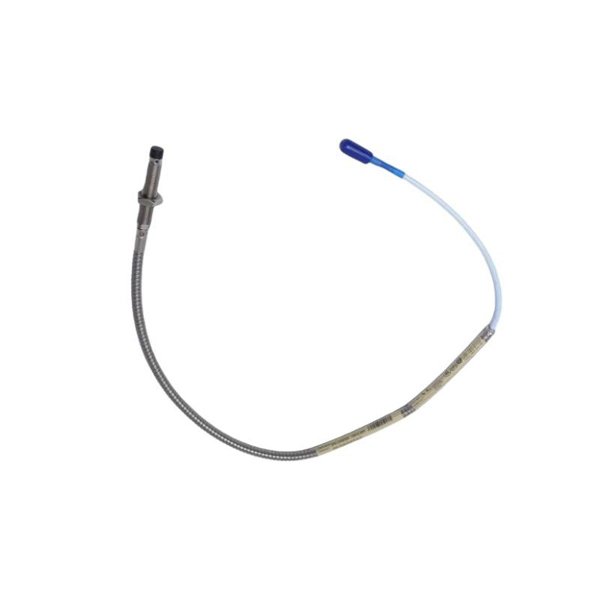

Bently Nevada 330104-00-05-05-02-CN 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-00-05-05-02-CN

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Dimensions:Total Length : 0.5 meter

Weight:0.161kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-00-05-05-02-CN 3300 XL 8 mm Proximity Probe is a high-precision, non-contact displacement sensor designed for use in machinery condition monitoring and vibration analysis. Part of the 3300 XL series, this probe is engineered to deliver accurate measurements of shaft vibration and position, enabling early detection of mechanical faults and enhancing predictive maintenance programs.

Constructed for durability and reliability, the probe is suited for demanding industrial environments and integrates seamlessly with Bently Nevada’s 3300 XL monitoring systems.

Key Features

-

8 mm diameter probe tip for accurate displacement sensing

-

Non-contact measurement technology to prevent wear and tear

-

Designed for compatibility with Bently Nevada 3300 XL systems

-

Constructed from corrosion-resistant and temperature-tolerant materials

-

Rugged design to withstand harsh industrial conditions

-

Low noise output ensures clear and precise signals

-

Suitable for critical rotating machinery monitoring

Technical Specifications

| Item | Specification |

|---|---|

| Manufacturer | Bently Nevada |

| Model Number | 330104-00-05-05-02-CN |

| Series | 3300 XL |

| Dimensions | Total Length : 0.5 meter |

| Tip Material | Hardened Stainless Steel |

| Operating Temperature | -40°C to +120°C |

| Vibration Frequency Range | DC to 20 kHz |

| Output Signal | AC Variable Reluctance |

| Connector Type | Integral flying lead |

| Weight | 0.161 kg |

| Application | Shaft vibration and position monitoring |

Industry Applications

-

Power Generation Turbines

-

Industrial Compressors

-

Large Electric Motors

-

Pumps and Fans in Process Plants

-

Petrochemical and Refinery Equipment

-

Heavy Manufacturing Machinery

Product Advantages

-

Precision Measurement: Provides highly accurate data for vibration and displacement

-

Durability: Built to withstand extreme temperatures and corrosive environments

-

System Compatibility: Designed for use with Bently Nevada 3300 XL monitoring platforms

-

Early Detection: Supports predictive maintenance by detecting faults early

-

Low Noise Output: Ensures clean signals for reliable condition monitoring

-

Rugged Construction: Suitable for use in demanding industrial settings

Frequently Asked Questions (FAQ)

-

Is this probe compatible with Bently Nevada 3300 XL systems?

Yes, it is fully compatible with the 3300 XL series.

-

What is the operating temperature range?

The probe operates safely between -40°C and +120°C.

-

What type of signal output does the probe provide?

AC variable reluctance signal.

-

What materials are used for the probe tip?

Hardened stainless steel for durability and corrosion resistance.

-

Can this probe operate in corrosive environments?

Yes, it is designed to withstand corrosive conditions.

-

What is the probe’s vibration frequency range?

It measures vibrations from DC up to 20 kHz.

-

How is the probe connected to the monitoring system?

Via an integral flying lead compatible with 3300 XL systems.

-

What industries commonly use this probe?

Power generation, petrochemical, heavy manufacturing, and process industries.

-

What is the probe’s physical size?

Length is 127 mm (5 inches), and diameter is 8 mm.

-

What advantages does non-contact measurement offer?

It reduces wear and maintenance needs, providing long-term reliability.

Bently Nevada 330104-00-05-05-02-CN 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-00-05-05-02-CN

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Dimensions:Total Length : 0.5 meter

Weight:0.161kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-00-05-05-02-CN 3300 XL 8 mm Proximity Probe is a high-precision, non-contact displacement sensor designed for use in machinery condition monitoring and vibration analysis. Part of the 3300 XL series, this probe is engineered to deliver accurate measurements of shaft vibration and position, enabling early detection of mechanical faults and enhancing predictive maintenance programs.

Constructed for durability and reliability, the probe is suited for demanding industrial environments and integrates seamlessly with Bently Nevada’s 3300 XL monitoring systems.

Key Features

-

8 mm diameter probe tip for accurate displacement sensing

-

Non-contact measurement technology to prevent wear and tear

-

Designed for compatibility with Bently Nevada 3300 XL systems

-

Constructed from corrosion-resistant and temperature-tolerant materials

-

Rugged design to withstand harsh industrial conditions

-

Low noise output ensures clear and precise signals

-

Suitable for critical rotating machinery monitoring

Technical Specifications

| Item | Specification |

|---|---|

| Manufacturer | Bently Nevada |

| Model Number | 330104-00-05-05-02-CN |

| Series | 3300 XL |

| Dimensions | Total Length : 0.5 meter |

| Tip Material | Hardened Stainless Steel |

| Operating Temperature | -40°C to +120°C |

| Vibration Frequency Range | DC to 20 kHz |

| Output Signal | AC Variable Reluctance |

| Connector Type | Integral flying lead |

| Weight | 0.161 kg |

| Application | Shaft vibration and position monitoring |

Industry Applications

-

Power Generation Turbines

-

Industrial Compressors

-

Large Electric Motors

-

Pumps and Fans in Process Plants

-

Petrochemical and Refinery Equipment

-

Heavy Manufacturing Machinery

Product Advantages

-

Precision Measurement: Provides highly accurate data for vibration and displacement

-

Durability: Built to withstand extreme temperatures and corrosive environments

-

System Compatibility: Designed for use with Bently Nevada 3300 XL monitoring platforms

-

Early Detection: Supports predictive maintenance by detecting faults early

-

Low Noise Output: Ensures clean signals for reliable condition monitoring

-

Rugged Construction: Suitable for use in demanding industrial settings

Frequently Asked Questions (FAQ)

-

Is this probe compatible with Bently Nevada 3300 XL systems?

Yes, it is fully compatible with the 3300 XL series.

-

What is the operating temperature range?

The probe operates safely between -40°C and +120°C.

-

What type of signal output does the probe provide?

AC variable reluctance signal.

-

What materials are used for the probe tip?

Hardened stainless steel for durability and corrosion resistance.

-

Can this probe operate in corrosive environments?

Yes, it is designed to withstand corrosive conditions.

-

What is the probe’s vibration frequency range?

It measures vibrations from DC up to 20 kHz.

-

How is the probe connected to the monitoring system?

Via an integral flying lead compatible with 3300 XL systems.

-

What industries commonly use this probe?

Power generation, petrochemical, heavy manufacturing, and process industries.

-

What is the probe’s physical size?

Length is 127 mm (5 inches), and diameter is 8 mm.

-

What advantages does non-contact measurement offer?

It reduces wear and maintenance needs, providing long-term reliability.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...