Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

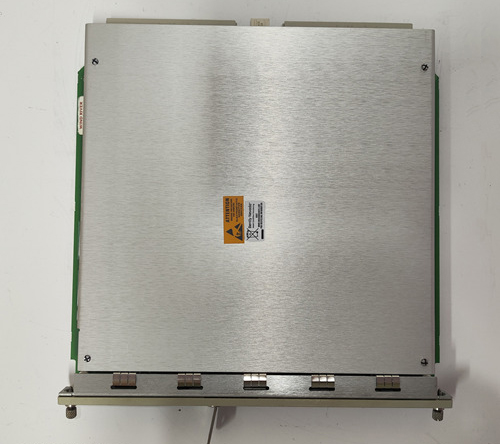

Bently Nevada 330103-06-14-20-01-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-06-14-20-01-00

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:2.0 meters

Weight:0.646 kg

Views:61

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-06-14-20-01-00 3300 XL 8 mm Proximity Probe is a high-precision sensor designed for monitoring shaft vibration and position in industrial rotating machinery. It delivers reliable measurement for both static (position) and dynamic (vibration) applications, ensuring compliance with API 670 standards. The 8 mm probe diameter and robust construction allow operation in demanding environments, including extreme temperatures and industrial mechanical stress.

Technical Specifications

| Parameter | Specification |

|---|---|

| Probe Type | 8 mm 3300 XL Proximity Probe |

| Thread Options | 3/8-24 UNF-2A or M10 x 1 |

| Cable Type | 75 Ω coaxial, optional FluidLoc for fluid containment |

| Connector | Miniature male coaxial ClickLoc connector |

| Operating Temperature | -40°C to +120°C |

| Total Length | 2.0 meters |

| Weight | 0.646 kg |

| Compliance | API 670 4th Edition |

| Measurement Range | ±0.050 inch typical |

| Accuracy | ±1% of full scale |

Applications

-

Vibration monitoring in high-speed rotating machinery

-

Oil, gas, and power generation sectors

-

Critical equipment requiring API 670 compliance

Advantages

-

High-precision measurements for both vibration and position

-

Durable design for extreme temperature and industrial environments

-

Easy integration with 3300 XL systems and backward compatibility

-

Flexible mounting options with multiple thread choices

-

Reliable and stable output with minimal drift over time

FAQ

1. What is the measurement range of this probe?

The typical measurement range is ±0.050 inch.

2. Is the probe compatible with non-XL 3300 series components?

Yes, it is backward-compatible with other 3300 series probes and extension cables.

3. What temperature range can it operate in?

The probe operates between -40°C and +120°C.

4. What type of cable does the probe use?

It uses a 75 Ω coaxial cable, with optional FluidLoc for fluid containment.

5. How precise is the probe output?

Accuracy is ±1% of full scale, suitable for API 670 compliance.

6. Can it measure both static and dynamic displacement?

Yes, it provides accurate measurements for both position and vibration.

7. What mounting options are available?

Standard, reverse, and smooth case mounting options are supported.

8. What connector type does the probe use?

It uses a miniature male coaxial ClickLoc connector.

9. How long is the cable provided with the probe?

The total length is 2.0 meters.

10. What industries commonly use this probe?

It is widely used in oil, gas, power generation, and heavy industrial applications.

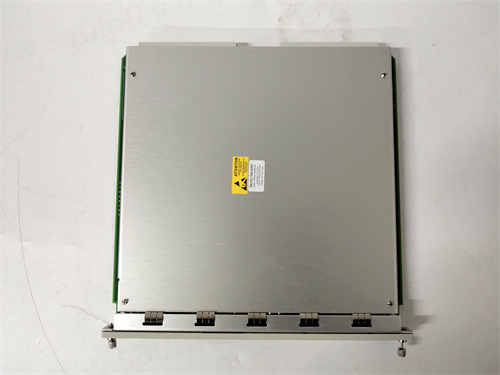

Bently Nevada 330103-06-14-20-01-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-06-14-20-01-00

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:2.0 meters

Weight:0.646 kg

Views:61

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-06-14-20-01-00 3300 XL 8 mm Proximity Probe is a high-precision sensor designed for monitoring shaft vibration and position in industrial rotating machinery. It delivers reliable measurement for both static (position) and dynamic (vibration) applications, ensuring compliance with API 670 standards. The 8 mm probe diameter and robust construction allow operation in demanding environments, including extreme temperatures and industrial mechanical stress.

Technical Specifications

| Parameter | Specification |

|---|---|

| Probe Type | 8 mm 3300 XL Proximity Probe |

| Thread Options | 3/8-24 UNF-2A or M10 x 1 |

| Cable Type | 75 Ω coaxial, optional FluidLoc for fluid containment |

| Connector | Miniature male coaxial ClickLoc connector |

| Operating Temperature | -40°C to +120°C |

| Total Length | 2.0 meters |

| Weight | 0.646 kg |

| Compliance | API 670 4th Edition |

| Measurement Range | ±0.050 inch typical |

| Accuracy | ±1% of full scale |

Applications

-

Vibration monitoring in high-speed rotating machinery

-

Oil, gas, and power generation sectors

-

Critical equipment requiring API 670 compliance

Advantages

-

High-precision measurements for both vibration and position

-

Durable design for extreme temperature and industrial environments

-

Easy integration with 3300 XL systems and backward compatibility

-

Flexible mounting options with multiple thread choices

-

Reliable and stable output with minimal drift over time

FAQ

1. What is the measurement range of this probe?

The typical measurement range is ±0.050 inch.

2. Is the probe compatible with non-XL 3300 series components?

Yes, it is backward-compatible with other 3300 series probes and extension cables.

3. What temperature range can it operate in?

The probe operates between -40°C and +120°C.

4. What type of cable does the probe use?

It uses a 75 Ω coaxial cable, with optional FluidLoc for fluid containment.

5. How precise is the probe output?

Accuracy is ±1% of full scale, suitable for API 670 compliance.

6. Can it measure both static and dynamic displacement?

Yes, it provides accurate measurements for both position and vibration.

7. What mounting options are available?

Standard, reverse, and smooth case mounting options are supported.

8. What connector type does the probe use?

It uses a miniature male coaxial ClickLoc connector.

9. How long is the cable provided with the probe?

The total length is 2.0 meters.

10. What industries commonly use this probe?

It is widely used in oil, gas, power generation, and heavy industrial applications.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...