Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

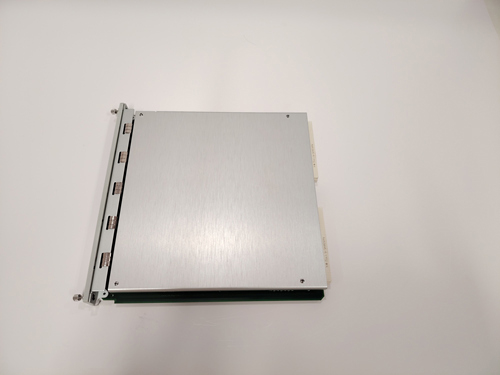

Bently Nevada 330103-06-11-10-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-06-11-10-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1.0 meter

Weight:0.323 kg

Views:24

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-06-11-10-02-05 is part of the 3300 XL 8 mm Proximity Transducer System, designed to provide highly reliable and accurate measurements of shaft vibration and position in rotating machinery. This probe features an M10 × 1 thread, no armor, and incorporates advanced mechanical bonding technologies for long-term durability. It operates as part of a three-component system, including the probe, extension cable, and Proximitor® sensor.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330103-06-11-10-02-05 |

| Probe Diameter | 8 mm |

| Thread Type | M10 × 1 |

| System Type | 3300 XL Proximity Transducer System |

| Standard Compliance | API 670 (4th edition) |

| Total Length | 1.0 m |

| Weight | 0.323 kg |

| Connector Type | ClickLoc™ miniature coaxial connector |

| Mounting Method | Threaded installation |

| Operating Range | Up to 2 mm linear measurement range |

| Temperature Range | -35 °C to +180 °C (probe only) |

| Cable Type | Unarmored, high-strength bonding with CableLoc™ |

| Compatibility | Backward compatible with older 3300 series 5 mm and 8 mm systems |

Applications

-

Monitoring shaft vibration in turbines, compressors, and pumps

-

Measuring rotor-to-stator clearance in large rotating equipment

-

Detecting shaft position and axial displacement

-

Ensuring API 670 compliance in critical machinery protection systems

-

Long-term condition monitoring in petrochemical, power generation, and process industries

Advantages

-

ClickLoc™ connectors: Gold-plated, secure locking design that prevents accidental disconnection.

-

TipLoc™ bonding: Prevents probe tip loosening under thermal or mechanical stress.

-

CableLoc™ reinforcement: Provides up to 330 N pull strength for cable durability.

-

High EMI/RFI immunity: Reliable performance in electrically noisy environments.

-

Backward compatibility: Works seamlessly with older 3300 5 mm and 8 mm components.

-

Global compliance: Meets API 670 and other international reliability standards.

FAQ

Q1: What does the model number 330103-06-11-10-02-05 specify?

A1: It defines the probe type, thread style, length, connector type, and specific configuration details required for the application.

Q2: Can this probe be used with older 3300 systems?

A2: Yes, it is backward compatible with 3300 series 5 mm and 8 mm components.

Q3: What is the primary function of the 330103 probe?

A3: To measure both static shaft position and dynamic vibration in rotating machinery.

Q4: What is the measurement range of the probe?

A4: It provides up to a 2 mm linear measurement range, suitable for shaft vibration monitoring.

Q5: How is the probe installed?

A5: It uses an M10 × 1 threaded mount for secure and precise positioning near the shaft surface.

Q6: What industries typically use this probe?

A6: Oil & gas, power generation, chemical processing, and heavy machinery sectors.

Q7: What makes the XL series more reliable than earlier designs?

A7: Features like ClickLoc™, TipLoc™, and CableLoc™ technologies improve durability and connection reliability.

Q8: Can the probe operate in high-temperature environments?

A8: Yes, it withstands probe tip temperatures up to +180 °C.

Q9: Is the probe designed for armored or unarmored cable use?

A9: This specific model uses an unarmored cable with reinforced CableLoc™ bonding.

Q10: What standard does the system comply with?

A10: It fully meets API 670 standards for machinery protection and monitoring.

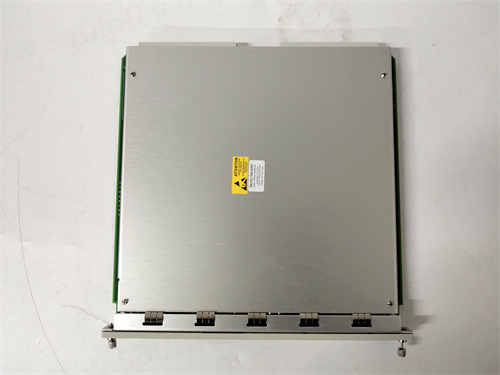

Bently Nevada 330103-06-11-10-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-06-11-10-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1.0 meter

Weight:0.323 kg

Views:24

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-06-11-10-02-05 is part of the 3300 XL 8 mm Proximity Transducer System, designed to provide highly reliable and accurate measurements of shaft vibration and position in rotating machinery. This probe features an M10 × 1 thread, no armor, and incorporates advanced mechanical bonding technologies for long-term durability. It operates as part of a three-component system, including the probe, extension cable, and Proximitor® sensor.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330103-06-11-10-02-05 |

| Probe Diameter | 8 mm |

| Thread Type | M10 × 1 |

| System Type | 3300 XL Proximity Transducer System |

| Standard Compliance | API 670 (4th edition) |

| Total Length | 1.0 m |

| Weight | 0.323 kg |

| Connector Type | ClickLoc™ miniature coaxial connector |

| Mounting Method | Threaded installation |

| Operating Range | Up to 2 mm linear measurement range |

| Temperature Range | -35 °C to +180 °C (probe only) |

| Cable Type | Unarmored, high-strength bonding with CableLoc™ |

| Compatibility | Backward compatible with older 3300 series 5 mm and 8 mm systems |

Applications

-

Monitoring shaft vibration in turbines, compressors, and pumps

-

Measuring rotor-to-stator clearance in large rotating equipment

-

Detecting shaft position and axial displacement

-

Ensuring API 670 compliance in critical machinery protection systems

-

Long-term condition monitoring in petrochemical, power generation, and process industries

Advantages

-

ClickLoc™ connectors: Gold-plated, secure locking design that prevents accidental disconnection.

-

TipLoc™ bonding: Prevents probe tip loosening under thermal or mechanical stress.

-

CableLoc™ reinforcement: Provides up to 330 N pull strength for cable durability.

-

High EMI/RFI immunity: Reliable performance in electrically noisy environments.

-

Backward compatibility: Works seamlessly with older 3300 5 mm and 8 mm components.

-

Global compliance: Meets API 670 and other international reliability standards.

FAQ

Q1: What does the model number 330103-06-11-10-02-05 specify?

A1: It defines the probe type, thread style, length, connector type, and specific configuration details required for the application.

Q2: Can this probe be used with older 3300 systems?

A2: Yes, it is backward compatible with 3300 series 5 mm and 8 mm components.

Q3: What is the primary function of the 330103 probe?

A3: To measure both static shaft position and dynamic vibration in rotating machinery.

Q4: What is the measurement range of the probe?

A4: It provides up to a 2 mm linear measurement range, suitable for shaft vibration monitoring.

Q5: How is the probe installed?

A5: It uses an M10 × 1 threaded mount for secure and precise positioning near the shaft surface.

Q6: What industries typically use this probe?

A6: Oil & gas, power generation, chemical processing, and heavy machinery sectors.

Q7: What makes the XL series more reliable than earlier designs?

A7: Features like ClickLoc™, TipLoc™, and CableLoc™ technologies improve durability and connection reliability.

Q8: Can the probe operate in high-temperature environments?

A8: Yes, it withstands probe tip temperatures up to +180 °C.

Q9: Is the probe designed for armored or unarmored cable use?

A9: This specific model uses an unarmored cable with reinforced CableLoc™ bonding.

Q10: What standard does the system comply with?

A10: It fully meets API 670 standards for machinery protection and monitoring.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...