Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

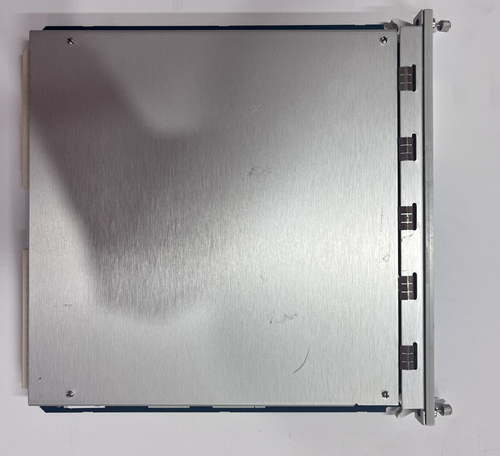

Bently Nevada 3500/25 125800-02 Isolated Keyphasor I/O Module

Manufacturer:Bently Nevada

Product Number:3500/25 125800-02

Product Type:Isolated Keyphasor I/O Module (Internal Terminations)

Origin:USA

Dimensions:241.3 x 24.4 x 103.1 mm

Weight:0.46 kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/25 125800-02 Isolated Keyphasor I/O Module is a critical component of the 3500 Machinery Protection System, specifically designed for keyphasor signal processing. The module provides isolated keyphasor inputs to the system, enabling accurate phase reference measurements for rotating machinery. It ensures high integrity and reliability by isolating input signals from the rest of the monitoring system, thus preventing unwanted noise interference and grounding issues.

This model, featuring internal terminations, is engineered for environments that demand precision in vibration monitoring, rotor speed measurement, and phase tracking. The isolation mechanism guarantees robust performance in complex industrial setups such as turbines, compressors, motors, and generators.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 3500/25 125800-02 |

| Product Type | Isolated Keyphasor I/O Module (Internal Terminations) |

| System Compatibility | Bently Nevada 3500 Monitoring System |

| Input Channels | Two independent isolated Keyphasor inputs |

| Signal Type Supported | TTL, magnetic pickup, proximity probe keyphasor signals |

| Input Frequency Range | 0.016 Hz to 20 kHz (depending on probe and installation) |

| Isolation Type | Galvanic isolation between inputs and system bus |

| Termination Type | Internal Terminations |

| Power Consumption | < 5 Watts (from 3500 rack backplane) |

| Operating Temperature | -30 °C to +65 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity | 95% non-condensing |

| Compliance & Standards | CE, CSA, ATEX, IECEx certified |

| Dimensions (H × W × D) | 241.3 x 24.4 x 103.1 mm |

| Weight | 0.46 kg |

Product Applications

The 3500/25 125800-02 is widely used in machinery protection and condition monitoring systems across multiple industries.

-

Turbomachinery Monitoring: Provides phase reference signals for steam, gas, and hydro turbines.

-

Compressor Protection: Essential for detecting torsional vibration and rotor dynamics in compressors.

-

Generator and Motor Monitoring: Enables precise speed and phase tracking for synchronous machines.

-

Rotating Equipment Diagnostics: Works in conjunction with vibration probes to deliver reliable diagnostics for shaft position and rotor speed.

-

Condition Monitoring Systems: Supplies reference pulses for order analysis, FFT diagnostics, and balancing operations.

Product Advantages

The Bently Nevada 3500/25 125800-02 offers several advantages that make it a preferred choice in industrial monitoring systems:

-

High Signal Integrity: Isolated inputs reduce electrical noise, enhancing signal reliability.

-

Robust Compatibility: Supports a wide range of input signal types, including proximity probes and magnetic pickups.

-

System Integration: Seamlessly integrates with the Bently Nevada 3500 series for comprehensive machinery protection.

-

Flexibility: Dual independent inputs allow monitoring of multiple keyphasor signals simultaneously.

-

Safety & Compliance: Certified to international safety and hazardous area standards.

-

Maintenance Efficiency: Internal terminations simplify wiring and reduce installation time.

-

High Reliability: Designed for mission-critical turbomachinery applications with continuous 24/7 operation.

FAQ

-

What type of keyphasor probes can be connected to the 3500/25 125800-02?

The module is compatible with proximity probes, magnetic pickups, and TTL-compatible sensors, allowing flexibility in connecting different types of keyphasor transducers.

-

How many independent inputs does the module support?

It supports two fully isolated keyphasor input channels, enabling simultaneous monitoring of multiple phase reference signals.

-

What is the maximum frequency range supported by this module?

The module can process input signals from as low as 0.016 Hz up to 20 kHz, depending on the probe type and installation conditions.

-

How does isolation benefit the monitoring system?

Electrical isolation eliminates ground loops and prevents signal interference, ensuring accurate, noise-free keyphasor signals across the system.

-

Can the module operate in high-temperature industrial environments?

Yes, it is designed for rugged conditions and can operate reliably within a temperature range of -30 °C to +65 °C.

-

Does the module require an external power supply?

No, the module draws its operating power directly from the 3500 rack backplane, simplifying installation and reducing wiring needs.

-

Is this module hot-swappable within the 3500 system rack?

Yes, it supports hot-swapping, which means it can be inserted or removed without shutting down the entire system.

-

What diagnostic features are built into the module?

The module provides continuous self-check diagnostics, including validation of input signal presence and integrity, to ensure reliable operation.

-

How does it contribute to rotor speed measurement?

It converts incoming keyphasor pulses into precise phase reference data, which is used for speed calculation, order tracking, and advanced vibration analysis.

-

Is it certified for hazardous area installations?

Yes, it meets ATEX and IECEx certifications, making it suitable for deployment in hazardous and explosive industrial environments.

Bently Nevada 3500/25 125800-02 Isolated Keyphasor I/O Module

Manufacturer:Bently Nevada

Product Number:3500/25 125800-02

Product Type:Isolated Keyphasor I/O Module (Internal Terminations)

Origin:USA

Dimensions:241.3 x 24.4 x 103.1 mm

Weight:0.46 kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/25 125800-02 Isolated Keyphasor I/O Module is a critical component of the 3500 Machinery Protection System, specifically designed for keyphasor signal processing. The module provides isolated keyphasor inputs to the system, enabling accurate phase reference measurements for rotating machinery. It ensures high integrity and reliability by isolating input signals from the rest of the monitoring system, thus preventing unwanted noise interference and grounding issues.

This model, featuring internal terminations, is engineered for environments that demand precision in vibration monitoring, rotor speed measurement, and phase tracking. The isolation mechanism guarantees robust performance in complex industrial setups such as turbines, compressors, motors, and generators.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 3500/25 125800-02 |

| Product Type | Isolated Keyphasor I/O Module (Internal Terminations) |

| System Compatibility | Bently Nevada 3500 Monitoring System |

| Input Channels | Two independent isolated Keyphasor inputs |

| Signal Type Supported | TTL, magnetic pickup, proximity probe keyphasor signals |

| Input Frequency Range | 0.016 Hz to 20 kHz (depending on probe and installation) |

| Isolation Type | Galvanic isolation between inputs and system bus |

| Termination Type | Internal Terminations |

| Power Consumption | < 5 Watts (from 3500 rack backplane) |

| Operating Temperature | -30 °C to +65 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity | 95% non-condensing |

| Compliance & Standards | CE, CSA, ATEX, IECEx certified |

| Dimensions (H × W × D) | 241.3 x 24.4 x 103.1 mm |

| Weight | 0.46 kg |

Product Applications

The 3500/25 125800-02 is widely used in machinery protection and condition monitoring systems across multiple industries.

-

Turbomachinery Monitoring: Provides phase reference signals for steam, gas, and hydro turbines.

-

Compressor Protection: Essential for detecting torsional vibration and rotor dynamics in compressors.

-

Generator and Motor Monitoring: Enables precise speed and phase tracking for synchronous machines.

-

Rotating Equipment Diagnostics: Works in conjunction with vibration probes to deliver reliable diagnostics for shaft position and rotor speed.

-

Condition Monitoring Systems: Supplies reference pulses for order analysis, FFT diagnostics, and balancing operations.

Product Advantages

The Bently Nevada 3500/25 125800-02 offers several advantages that make it a preferred choice in industrial monitoring systems:

-

High Signal Integrity: Isolated inputs reduce electrical noise, enhancing signal reliability.

-

Robust Compatibility: Supports a wide range of input signal types, including proximity probes and magnetic pickups.

-

System Integration: Seamlessly integrates with the Bently Nevada 3500 series for comprehensive machinery protection.

-

Flexibility: Dual independent inputs allow monitoring of multiple keyphasor signals simultaneously.

-

Safety & Compliance: Certified to international safety and hazardous area standards.

-

Maintenance Efficiency: Internal terminations simplify wiring and reduce installation time.

-

High Reliability: Designed for mission-critical turbomachinery applications with continuous 24/7 operation.

FAQ

-

What type of keyphasor probes can be connected to the 3500/25 125800-02?

The module is compatible with proximity probes, magnetic pickups, and TTL-compatible sensors, allowing flexibility in connecting different types of keyphasor transducers.

-

How many independent inputs does the module support?

It supports two fully isolated keyphasor input channels, enabling simultaneous monitoring of multiple phase reference signals.

-

What is the maximum frequency range supported by this module?

The module can process input signals from as low as 0.016 Hz up to 20 kHz, depending on the probe type and installation conditions.

-

How does isolation benefit the monitoring system?

Electrical isolation eliminates ground loops and prevents signal interference, ensuring accurate, noise-free keyphasor signals across the system.

-

Can the module operate in high-temperature industrial environments?

Yes, it is designed for rugged conditions and can operate reliably within a temperature range of -30 °C to +65 °C.

-

Does the module require an external power supply?

No, the module draws its operating power directly from the 3500 rack backplane, simplifying installation and reducing wiring needs.

-

Is this module hot-swappable within the 3500 system rack?

Yes, it supports hot-swapping, which means it can be inserted or removed without shutting down the entire system.

-

What diagnostic features are built into the module?

The module provides continuous self-check diagnostics, including validation of input signal presence and integrity, to ensure reliable operation.

-

How does it contribute to rotor speed measurement?

It converts incoming keyphasor pulses into precise phase reference data, which is used for speed calculation, order tracking, and advanced vibration analysis.

-

Is it certified for hazardous area installations?

Yes, it meets ATEX and IECEx certifications, making it suitable for deployment in hazardous and explosive industrial environments.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...