Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

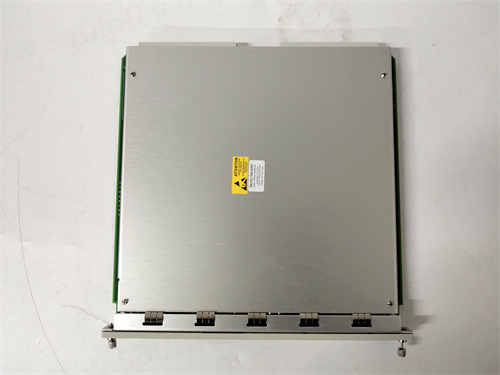

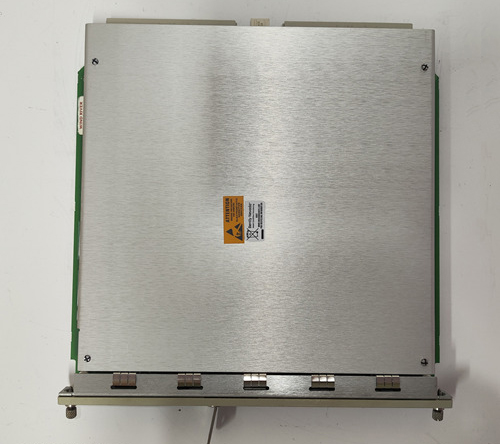

Bently Nevada 330102-00-16-10-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number: 330102-00-16-10-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1m

Weight :0.323 kg

Views:55

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330102-00-16-10-02-05 – 3300 XL 8 mm Proximity Probe is a high-performance non-contact sensor designed to measure shaft vibration, displacement, and position in critical rotating machinery. As part of the 3300 XL series, this probe offers extended linear measurement range, superior temperature stability, and long-term reliability in demanding industrial environments.

The probe works with a matching extension cable and proximity sensor driver to deliver accurate condition monitoring signals directly to protection and monitoring systems. It is widely deployed in turbines, compressors, pumps, gearboxes, and other high-value equipment where precise shaft measurements are essential for predictive maintenance and safe operation.

Product Parameters

| Parameter | Description |

|---|---|

| Model Number | 330102-00-16-10-02-05 |

| Series | 3300 XL 8 mm Proximity Probe |

| Measurement Range | 200 mils (5.08 mm) typical linear range |

| Tip Diameter | 8 mm (standard sensing tip) |

| Thread Size | M10 × 1 or 3/8-24 UNF (depending on variant) |

| Material | Stainless steel probe body, polymer insulated cable |

| Operating Temperature | -35 °C to +180 °C (probe) |

| Frequency Response | DC to 10 kHz (typical) |

| Power Supply | Supplied through proximitor driver (–24 VDC nominal) |

| Insulation Resistance | > 10^9 Ω at 500 VDC |

| Vibration Limit | 20 g peak (10–2000 Hz) |

| Shock Limit | 500 g, 1 ms duration |

| Total Length | 1 m |

| Weight | 0.323 kg |

Product Applications

-

Steam and Gas Turbines – monitoring rotor vibration, thrust position, and bearing clearances.

-

Centrifugal Compressors – detection of shaft instability, imbalance, and misalignment.

-

Industrial Pumps – providing protection against excessive shaft displacement and mechanical wear.

-

Gearboxes and Motors – ensuring reliable operation by monitoring dynamic shaft behavior.

-

Predictive Maintenance Systems – integrated with condition monitoring systems to prevent failures.

-

Nuclear and Power Generation Plants – used in safety-critical vibration monitoring applications.

Product Advantages

-

Extended Linear Range – delivers consistent and accurate measurements up to 200 mils (5.08 mm).

-

High Temperature Stability – maintains accuracy across a wide operating range of –35 °C to +180 °C.

-

Robust Construction – stainless steel body and rugged cable design ensure long service life.

-

Compatibility – fully compatible with Bently Nevada proximitor drivers and extension cables.

-

High Accuracy and Reliability – minimizes signal drift and guarantees long-term stability.

-

Wide Industrial Acceptance – globally recognized as an industry standard in shaft vibration monitoring.

FAQ

Q1: What is the primary function of the 330102-00-16-10-02-05 proximity probe?

A1: It is used to measure shaft vibration, displacement, and position in rotating machinery, providing inputs for protection and condition monitoring systems.

Q2: Can this probe be used with any proximitor driver?

A2: No. It must be used with the corresponding 3300 XL extension cable and proximitor driver to ensure accuracy and proper calibration.

Q3: What is the difference between the 8 mm probe and the 5 mm probe?

A3: The 8 mm probe provides a larger linear measurement range, making it suitable for larger shaft sizes and high-dynamic applications, while the 5 mm probe is for more compact installations.

Q4: How long is the standard probe cable?

A4: This model comes with a 1.0 m integral cable, which must be connected to an extension cable to reach the proximitor driver.

Q5: What industries commonly use this probe?

A5: Oil and gas, petrochemical, power generation, steel, paper, and other heavy industries with critical rotating equipment.

Q6: Can the probe withstand high vibration environments?

A6: Yes, it can tolerate up to 20 g vibration and up to 500 g shock, making it reliable under severe operating conditions.

Q7: Is the probe interchangeable with older Bently Nevada probes?

A7: In most cases yes, but the 3300 XL series has specific compatibility requirements. It is recommended to use probes, extension cables, and drivers from the same series.

Q8: What maintenance does this probe require?

A8: Probes generally require no internal maintenance but should be periodically inspected for cable wear, connector integrity, and mounting security.

Q9: Can it be installed in hazardous environments?

A9: Yes, when used with certified accessories, the probe can be installed in hazardous and explosive classified areas.

Q10: How does the probe connect to the monitoring system?

A10: It connects via the extension cable to a proximitor driver, which then outputs a voltage signal proportional to shaft displacement for use in monitoring systems.

Bently Nevada 330102-00-16-10-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number: 330102-00-16-10-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1m

Weight :0.323 kg

Views:55

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330102-00-16-10-02-05 – 3300 XL 8 mm Proximity Probe is a high-performance non-contact sensor designed to measure shaft vibration, displacement, and position in critical rotating machinery. As part of the 3300 XL series, this probe offers extended linear measurement range, superior temperature stability, and long-term reliability in demanding industrial environments.

The probe works with a matching extension cable and proximity sensor driver to deliver accurate condition monitoring signals directly to protection and monitoring systems. It is widely deployed in turbines, compressors, pumps, gearboxes, and other high-value equipment where precise shaft measurements are essential for predictive maintenance and safe operation.

Product Parameters

| Parameter | Description |

|---|---|

| Model Number | 330102-00-16-10-02-05 |

| Series | 3300 XL 8 mm Proximity Probe |

| Measurement Range | 200 mils (5.08 mm) typical linear range |

| Tip Diameter | 8 mm (standard sensing tip) |

| Thread Size | M10 × 1 or 3/8-24 UNF (depending on variant) |

| Material | Stainless steel probe body, polymer insulated cable |

| Operating Temperature | -35 °C to +180 °C (probe) |

| Frequency Response | DC to 10 kHz (typical) |

| Power Supply | Supplied through proximitor driver (–24 VDC nominal) |

| Insulation Resistance | > 10^9 Ω at 500 VDC |

| Vibration Limit | 20 g peak (10–2000 Hz) |

| Shock Limit | 500 g, 1 ms duration |

| Total Length | 1 m |

| Weight | 0.323 kg |

Product Applications

-

Steam and Gas Turbines – monitoring rotor vibration, thrust position, and bearing clearances.

-

Centrifugal Compressors – detection of shaft instability, imbalance, and misalignment.

-

Industrial Pumps – providing protection against excessive shaft displacement and mechanical wear.

-

Gearboxes and Motors – ensuring reliable operation by monitoring dynamic shaft behavior.

-

Predictive Maintenance Systems – integrated with condition monitoring systems to prevent failures.

-

Nuclear and Power Generation Plants – used in safety-critical vibration monitoring applications.

Product Advantages

-

Extended Linear Range – delivers consistent and accurate measurements up to 200 mils (5.08 mm).

-

High Temperature Stability – maintains accuracy across a wide operating range of –35 °C to +180 °C.

-

Robust Construction – stainless steel body and rugged cable design ensure long service life.

-

Compatibility – fully compatible with Bently Nevada proximitor drivers and extension cables.

-

High Accuracy and Reliability – minimizes signal drift and guarantees long-term stability.

-

Wide Industrial Acceptance – globally recognized as an industry standard in shaft vibration monitoring.

FAQ

Q1: What is the primary function of the 330102-00-16-10-02-05 proximity probe?

A1: It is used to measure shaft vibration, displacement, and position in rotating machinery, providing inputs for protection and condition monitoring systems.

Q2: Can this probe be used with any proximitor driver?

A2: No. It must be used with the corresponding 3300 XL extension cable and proximitor driver to ensure accuracy and proper calibration.

Q3: What is the difference between the 8 mm probe and the 5 mm probe?

A3: The 8 mm probe provides a larger linear measurement range, making it suitable for larger shaft sizes and high-dynamic applications, while the 5 mm probe is for more compact installations.

Q4: How long is the standard probe cable?

A4: This model comes with a 1.0 m integral cable, which must be connected to an extension cable to reach the proximitor driver.

Q5: What industries commonly use this probe?

A5: Oil and gas, petrochemical, power generation, steel, paper, and other heavy industries with critical rotating equipment.

Q6: Can the probe withstand high vibration environments?

A6: Yes, it can tolerate up to 20 g vibration and up to 500 g shock, making it reliable under severe operating conditions.

Q7: Is the probe interchangeable with older Bently Nevada probes?

A7: In most cases yes, but the 3300 XL series has specific compatibility requirements. It is recommended to use probes, extension cables, and drivers from the same series.

Q8: What maintenance does this probe require?

A8: Probes generally require no internal maintenance but should be periodically inspected for cable wear, connector integrity, and mounting security.

Q9: Can it be installed in hazardous environments?

A9: Yes, when used with certified accessories, the probe can be installed in hazardous and explosive classified areas.

Q10: How does the probe connect to the monitoring system?

A10: It connects via the extension cable to a proximitor driver, which then outputs a voltage signal proportional to shaft displacement for use in monitoring systems.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...