Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

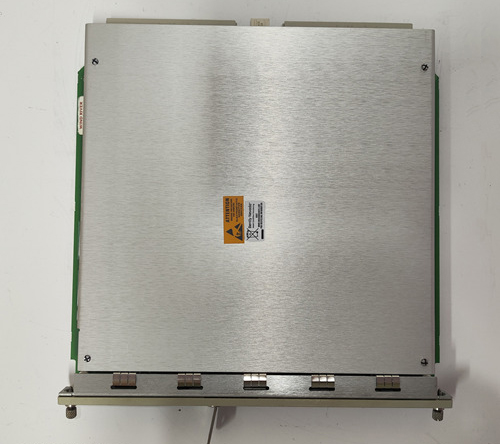

Bently Nevada 330101-00-10-10-02-05 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330101-00-10-10-02-05

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:67

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-10-10-02-05 is a high-precision, non-contact proximity probe engineered for use in the 3300 XL 8mm Proximity Transducer System. This system is globally recognized for delivering accurate measurements of shaft vibration, axial position, and rotational speed in rotating machinery, contributing to reliable machinery protection and predictive maintenance strategies.

This specific model features an 8mm probe tip diameter, a system cable length of 10 feet (including the probe and extension cable), and armored construction with a connector protector option “05”, indicating enhanced environmental protection and mechanical stability. It is paired with the 3300 XL Proximitor Sensor and is ideally suited for continuous monitoring in harsh industrial environments, including oil refineries, gas plants, and power stations.

The 330101-00-10-10-02-05 is designed to comply with API 670 standards, ensuring its suitability for critical turbomachinery monitoring applications.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 330101-00-10-10-02-05 |

| Series | 3300 XL 8mm |

| Sensor Type | Eddy Current Proximity Probe (Non-contact) |

| Tip Diameter | 8 mm (0.31 in) |

| Cable Length (System) | 10 feet (includes probe and extension cable) |

| Connector | ClickLoc™ Miniature Coaxial with Connector Protector (Option 05) |

| Mounting Thread | 1/4-28 UNF-2A |

| Body Style | Unthreaded, Armored Cable |

| Target Material | Calibrated for AISI 4140 steel |

| Linear Range | 2 mm (80 mils) |

| Non-linearity | Within ±0.25% of full-scale |

| Output Voltage | Typically -200 mV/mil (≈ -7.87 mV/µm) |

| Temperature Range | -35°C to +177°C (-31°F to +350°F) |

| Enclosure Rating | IP65 (with proper installation) |

| Compliance Standards | API 670, CE, RoHS |

| Weight | 0.323 kg |

| Total Length | 1.0 meter |

Applications

The Bently Nevada 330101-00-10-10-02-05 probe is widely implemented in industrial and critical rotating machinery applications due to its precision and robust design. Its primary uses include:

-

Steam & Gas Turbine Monitoring

Measures shaft vibration and axial position, essential for turbine protection.

-

Compressor Vibration Analysis

Integral to dynamic condition monitoring of centrifugal and reciprocating compressors.

-

Motor and Generator Monitoring

Detects early signs of mechanical degradation in critical assets.

-

Pump Condition Monitoring

Monitors bearing wear, imbalance, and misalignment in high-speed pump systems.

-

Thrust Bearing Wear Detection

Measures shaft displacement for thrust wear and axial misalignment.

-

Predictive Maintenance Programs

Deployed as part of online condition monitoring systems to reduce unplanned downtime.

Product Advantages

-

High Environmental Resistance

Equipped with option 05 connector protector, ensuring excellent performance in dusty, humid, and high-vibration environments.

-

Reliable Long-Term Stability

Minimal signal drift over extended operating periods, reducing recalibration needs.

-

API 670 Certified

Fully meets API 670 guidelines for machine protection systems, offering industry-standard assurance.

-

Mechanical Durability

Armored cable and stainless-steel probe housing withstand rough handling and industrial conditions.

-

Flexible Integration

Compatible with standard 3300 XL Proximitor Sensors and extension cables, offering modularity.

-

Non-Invasive Measurement

Eddy current sensing offers accurate measurements without physical contact, minimizing wear.

Frequently Asked Questions (FAQ)

1. What does the part number 330101-00-10-10-02-05 represent?

This part number indicates a 3300 XL 8mm probe with 10-foot cable length, armored body, and connector protection option 05.

2. Is this probe suitable for use in hazardous areas?

It can be used in hazardous areas when installed within an approved system or housing that complies with hazardous location certifications.

3. Can I install the probe in a vertical orientation?

Yes, the probe functions accurately in any orientation as long as the probe tip is properly aligned with the target surface.

4. How often should the probe be recalibrated?

It is factory calibrated and typically does not require frequent recalibration. However, annual verification is recommended in critical applications.

5. What type of connector is used on this model?

It uses the ClickLoc™ miniature coaxial connector with an additional connector protector for improved reliability.

6. How is this probe different from the standard 330101 model?

The 3330101 version includes added mechanical and environmental protection (option 05) and may have enhanced durability in harsh environments.

7. Can this be used in high-temperature environments?

Yes, it operates reliably up to 177°C (350°F), making it suitable for high-temperature industrial settings.

8. What sensor does it pair with?

It is designed to work with the 3300 XL Proximitor Sensor and the appropriate extension cable for a complete system.

9. Is it compatible with Keyphasor™ measurements?

Yes, when used in the appropriate configuration, it can support Keyphasor applications for speed and phase reference.

10. What installation tools are recommended?

Use a torque wrench for the mounting threads and follow Bently Nevada’s installation manual for gap adjustment and alignment.

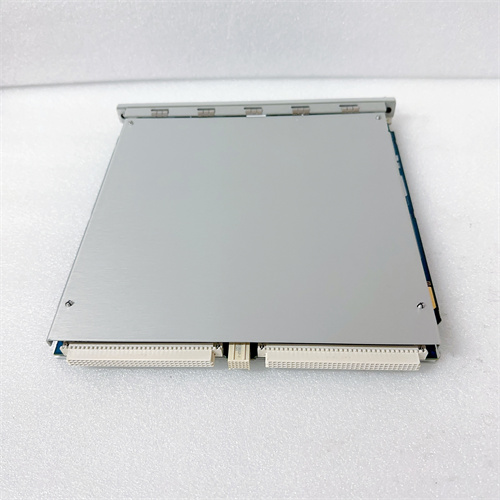

Bently Nevada 330101-00-10-10-02-05 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330101-00-10-10-02-05

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:67

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-10-10-02-05 is a high-precision, non-contact proximity probe engineered for use in the 3300 XL 8mm Proximity Transducer System. This system is globally recognized for delivering accurate measurements of shaft vibration, axial position, and rotational speed in rotating machinery, contributing to reliable machinery protection and predictive maintenance strategies.

This specific model features an 8mm probe tip diameter, a system cable length of 10 feet (including the probe and extension cable), and armored construction with a connector protector option “05”, indicating enhanced environmental protection and mechanical stability. It is paired with the 3300 XL Proximitor Sensor and is ideally suited for continuous monitoring in harsh industrial environments, including oil refineries, gas plants, and power stations.

The 330101-00-10-10-02-05 is designed to comply with API 670 standards, ensuring its suitability for critical turbomachinery monitoring applications.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 330101-00-10-10-02-05 |

| Series | 3300 XL 8mm |

| Sensor Type | Eddy Current Proximity Probe (Non-contact) |

| Tip Diameter | 8 mm (0.31 in) |

| Cable Length (System) | 10 feet (includes probe and extension cable) |

| Connector | ClickLoc™ Miniature Coaxial with Connector Protector (Option 05) |

| Mounting Thread | 1/4-28 UNF-2A |

| Body Style | Unthreaded, Armored Cable |

| Target Material | Calibrated for AISI 4140 steel |

| Linear Range | 2 mm (80 mils) |

| Non-linearity | Within ±0.25% of full-scale |

| Output Voltage | Typically -200 mV/mil (≈ -7.87 mV/µm) |

| Temperature Range | -35°C to +177°C (-31°F to +350°F) |

| Enclosure Rating | IP65 (with proper installation) |

| Compliance Standards | API 670, CE, RoHS |

| Weight | 0.323 kg |

| Total Length | 1.0 meter |

Applications

The Bently Nevada 330101-00-10-10-02-05 probe is widely implemented in industrial and critical rotating machinery applications due to its precision and robust design. Its primary uses include:

-

Steam & Gas Turbine Monitoring

Measures shaft vibration and axial position, essential for turbine protection.

-

Compressor Vibration Analysis

Integral to dynamic condition monitoring of centrifugal and reciprocating compressors.

-

Motor and Generator Monitoring

Detects early signs of mechanical degradation in critical assets.

-

Pump Condition Monitoring

Monitors bearing wear, imbalance, and misalignment in high-speed pump systems.

-

Thrust Bearing Wear Detection

Measures shaft displacement for thrust wear and axial misalignment.

-

Predictive Maintenance Programs

Deployed as part of online condition monitoring systems to reduce unplanned downtime.

Product Advantages

-

High Environmental Resistance

Equipped with option 05 connector protector, ensuring excellent performance in dusty, humid, and high-vibration environments.

-

Reliable Long-Term Stability

Minimal signal drift over extended operating periods, reducing recalibration needs.

-

API 670 Certified

Fully meets API 670 guidelines for machine protection systems, offering industry-standard assurance.

-

Mechanical Durability

Armored cable and stainless-steel probe housing withstand rough handling and industrial conditions.

-

Flexible Integration

Compatible with standard 3300 XL Proximitor Sensors and extension cables, offering modularity.

-

Non-Invasive Measurement

Eddy current sensing offers accurate measurements without physical contact, minimizing wear.

Frequently Asked Questions (FAQ)

1. What does the part number 330101-00-10-10-02-05 represent?

This part number indicates a 3300 XL 8mm probe with 10-foot cable length, armored body, and connector protection option 05.

2. Is this probe suitable for use in hazardous areas?

It can be used in hazardous areas when installed within an approved system or housing that complies with hazardous location certifications.

3. Can I install the probe in a vertical orientation?

Yes, the probe functions accurately in any orientation as long as the probe tip is properly aligned with the target surface.

4. How often should the probe be recalibrated?

It is factory calibrated and typically does not require frequent recalibration. However, annual verification is recommended in critical applications.

5. What type of connector is used on this model?

It uses the ClickLoc™ miniature coaxial connector with an additional connector protector for improved reliability.

6. How is this probe different from the standard 330101 model?

The 3330101 version includes added mechanical and environmental protection (option 05) and may have enhanced durability in harsh environments.

7. Can this be used in high-temperature environments?

Yes, it operates reliably up to 177°C (350°F), making it suitable for high-temperature industrial settings.

8. What sensor does it pair with?

It is designed to work with the 3300 XL Proximitor Sensor and the appropriate extension cable for a complete system.

9. Is it compatible with Keyphasor™ measurements?

Yes, when used in the appropriate configuration, it can support Keyphasor applications for speed and phase reference.

10. What installation tools are recommended?

Use a torque wrench for the mounting threads and follow Bently Nevada’s installation manual for gap adjustment and alignment.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...