Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

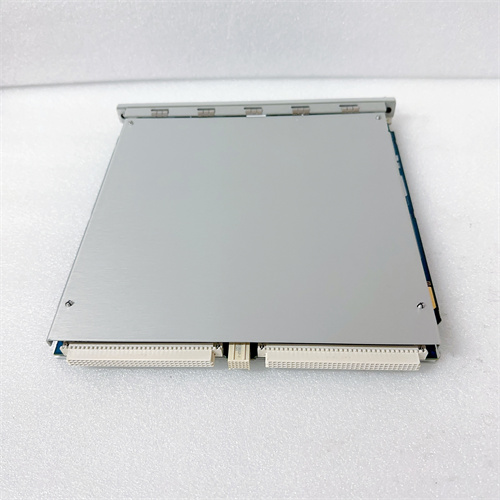

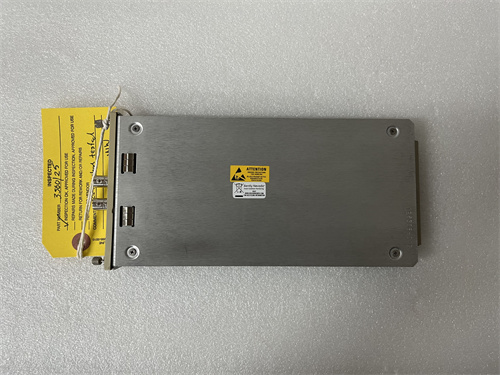

Bently Nevada 330103-03-10-15-01-05 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330103-03-10-15-01-05

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1.5 meters

Weight:0.485 kg

Views:11

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-03-10-15-01-05 3300 XL 8mm Proximity Probe is a precision-engineered sensor designed for high-performance vibration and displacement measurement in industrial machinery. As part of the widely recognized 3300 XL 8mm series, this probe ensures highly reliable shaft position and vibration monitoring, enabling plant operators to maintain machinery health and reduce downtime.

Built with robust materials and advanced electromagnetic sensing technology, this probe delivers consistent performance even in harsh industrial environments. The 330103-03-10-15-01-05 is designed to be fully compatible with Bently Nevada’s 3300 monitoring systems, offering seamless integration and trusted accuracy for critical machinery protection applications.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 330103-03-10-15-01-05 |

| Series | 3300 XL 8mm Proximity Probes |

| Probe Tip Diameter | 8 mm |

| Linear Range | 2 mm (80 mils) |

| Sensitivity | 7.87 mV/µm (200 mV/mil) |

| Frequency Response | 0 to 10 kHz |

| Operating Temperature | -35 °C to +180 °C |

| Storage Temperature | -55 °C to +100 °C |

| Total Length | 1.5 meters |

| Weight | 0.485 kg |

| Insulation Resistance | > 10^9 ohms |

| Material | Stainless steel housing, PEEK cable jacket |

| Compatibility | Bently Nevada 3300 Monitoring Systems |

Product Applications

The 330103-03-10-15-01-05 probe is widely applied across industries where precise machinery monitoring is critical. Its main applications include:

Turbomachinery Monitoring: Detects shaft vibration and position changes in turbines, compressors, and expanders.

Pumps and Motors: Ensures reliable detection of rotor-to-stator clearances and vibration.

Generators: Monitors shaft behavior to prevent damage from excessive vibration.

Gearboxes: Identifies misalignments and gear wear by tracking displacement trends.

Industrial Rotating Equipment: Ensures predictive maintenance strategies and machinery protection in petrochemical, oil & gas, and power generation facilities.

Product Advantages

High Measurement Accuracy: Offers stable sensitivity and linearity across a wide operating range.

Robust Design: Stainless steel probe housing and PEEK cable ensure durability in high-temperature and corrosive environments.

Seamless System Integration: Fully compatible with Bently Nevada 3300 systems, simplifying installation and calibration.

Wide Operating Range: Suitable for extreme industrial environments with broad temperature tolerance.

Reliable Machinery Protection: Enables early detection of faults, reducing unplanned shutdowns and maintenance costs.

Proven Reliability: Built on Bently Nevada’s long-standing reputation in condition monitoring technology.

FAQ

What is the primary function of the 330103-03-10-15-01-05 probe?

The probe measures shaft vibration and displacement by detecting variations in the electromagnetic field between the probe tip and the shaft surface, ensuring accurate real-time monitoring.

How does this probe interface with monitoring systems?

It connects to an extension cable and proximitor, which condition the signal and deliver a calibrated voltage output directly into the Bently Nevada 3300 series monitoring system.

What is the significance of the 8mm probe tip diameter?

The 8mm tip size provides enhanced resolution and sensitivity, making it suitable for applications where precise shaft position measurement within limited clearances is essential.

Can the probe operate in high-temperature environments?

Yes, the probe is designed for continuous operation in environments ranging from -35 °C to +180 °C, allowing reliable performance near turbines, compressors, and other high-temperature machinery.

How does cable length affect probe performance?

The probe and extension cable are factory-matched to maintain signal calibration. Using incorrect cable lengths or substitutions may cause measurement inaccuracies.

What type of signal output does the probe provide?

The probe generates a voltage signal that is proportional to the distance between the probe tip and the shaft, with a typical sensitivity of 7.87 mV/µm (200 mV/mil).

Is electromagnetic interference a concern for this probe?

No, the probe is shielded against electromagnetic and radio-frequency interference, ensuring reliable signal transmission in demanding industrial environments.

What is the linear measuring range of this probe?

The probe offers a linear measurement range of 2 mm (80 mils), providing accurate vibration and displacement readings for most rotating machinery.

Can the probe be used with non-Bently Nevada monitoring systems?

While optimized for Bently Nevada systems, it may be integrated with third-party systems if signal conditioning and calibration are properly managed.

How does the probe contribute to predictive maintenance?

By continuously monitoring shaft vibration and displacement, the probe enables early detection of issues such as imbalance, misalignment, or bearing wear, supporting proactive and predictive maintenance strategies.

Bently Nevada 330103-03-10-15-01-05 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330103-03-10-15-01-05

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1.5 meters

Weight:0.485 kg

Views:11

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-03-10-15-01-05 3300 XL 8mm Proximity Probe is a precision-engineered sensor designed for high-performance vibration and displacement measurement in industrial machinery. As part of the widely recognized 3300 XL 8mm series, this probe ensures highly reliable shaft position and vibration monitoring, enabling plant operators to maintain machinery health and reduce downtime.

Built with robust materials and advanced electromagnetic sensing technology, this probe delivers consistent performance even in harsh industrial environments. The 330103-03-10-15-01-05 is designed to be fully compatible with Bently Nevada’s 3300 monitoring systems, offering seamless integration and trusted accuracy for critical machinery protection applications.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 330103-03-10-15-01-05 |

| Series | 3300 XL 8mm Proximity Probes |

| Probe Tip Diameter | 8 mm |

| Linear Range | 2 mm (80 mils) |

| Sensitivity | 7.87 mV/µm (200 mV/mil) |

| Frequency Response | 0 to 10 kHz |

| Operating Temperature | -35 °C to +180 °C |

| Storage Temperature | -55 °C to +100 °C |

| Total Length | 1.5 meters |

| Weight | 0.485 kg |

| Insulation Resistance | > 10^9 ohms |

| Material | Stainless steel housing, PEEK cable jacket |

| Compatibility | Bently Nevada 3300 Monitoring Systems |

Product Applications

The 330103-03-10-15-01-05 probe is widely applied across industries where precise machinery monitoring is critical. Its main applications include:

Turbomachinery Monitoring: Detects shaft vibration and position changes in turbines, compressors, and expanders.

Pumps and Motors: Ensures reliable detection of rotor-to-stator clearances and vibration.

Generators: Monitors shaft behavior to prevent damage from excessive vibration.

Gearboxes: Identifies misalignments and gear wear by tracking displacement trends.

Industrial Rotating Equipment: Ensures predictive maintenance strategies and machinery protection in petrochemical, oil & gas, and power generation facilities.

Product Advantages

High Measurement Accuracy: Offers stable sensitivity and linearity across a wide operating range.

Robust Design: Stainless steel probe housing and PEEK cable ensure durability in high-temperature and corrosive environments.

Seamless System Integration: Fully compatible with Bently Nevada 3300 systems, simplifying installation and calibration.

Wide Operating Range: Suitable for extreme industrial environments with broad temperature tolerance.

Reliable Machinery Protection: Enables early detection of faults, reducing unplanned shutdowns and maintenance costs.

Proven Reliability: Built on Bently Nevada’s long-standing reputation in condition monitoring technology.

FAQ

What is the primary function of the 330103-03-10-15-01-05 probe?

The probe measures shaft vibration and displacement by detecting variations in the electromagnetic field between the probe tip and the shaft surface, ensuring accurate real-time monitoring.

How does this probe interface with monitoring systems?

It connects to an extension cable and proximitor, which condition the signal and deliver a calibrated voltage output directly into the Bently Nevada 3300 series monitoring system.

What is the significance of the 8mm probe tip diameter?

The 8mm tip size provides enhanced resolution and sensitivity, making it suitable for applications where precise shaft position measurement within limited clearances is essential.

Can the probe operate in high-temperature environments?

Yes, the probe is designed for continuous operation in environments ranging from -35 °C to +180 °C, allowing reliable performance near turbines, compressors, and other high-temperature machinery.

How does cable length affect probe performance?

The probe and extension cable are factory-matched to maintain signal calibration. Using incorrect cable lengths or substitutions may cause measurement inaccuracies.

What type of signal output does the probe provide?

The probe generates a voltage signal that is proportional to the distance between the probe tip and the shaft, with a typical sensitivity of 7.87 mV/µm (200 mV/mil).

Is electromagnetic interference a concern for this probe?

No, the probe is shielded against electromagnetic and radio-frequency interference, ensuring reliable signal transmission in demanding industrial environments.

What is the linear measuring range of this probe?

The probe offers a linear measurement range of 2 mm (80 mils), providing accurate vibration and displacement readings for most rotating machinery.

Can the probe be used with non-Bently Nevada monitoring systems?

While optimized for Bently Nevada systems, it may be integrated with third-party systems if signal conditioning and calibration are properly managed.

How does the probe contribute to predictive maintenance?

By continuously monitoring shaft vibration and displacement, the probe enables early detection of issues such as imbalance, misalignment, or bearing wear, supporting proactive and predictive maintenance strategies.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...